The Complete Guide to 2K Injection Molding & Dual Material Tooling

In today's competitive market, product designers and engineers are constantly challenged to create products that are not only functional but also ergonomic, aesthetically pleasing, and highly durable. Achieving this often requires combining different materials—a hard, rigid structure with a soft, flexible grip, for example. Traditionally, this meant molding separate parts and joining them through a secondary assembly process, which adds time, cost, and potential points of failure.

2K injection molding is the definitive manufacturing solution that solves this challenge. It is an advanced process that fabricates complex, multi-material parts in a single, highly efficient machine cycle. By integrating different polymers into one component, it unlocks a new level of design freedom and product performance.

As a leader in precision mold making and injection molding with over 25 years of experience, SunOn Mould has mastered the intricacies of dual material tooling and the 2K process. This guide consolidates that deep expertise to provide a comprehensive resource for engineers, designers, and project managers looking to leverage this transformative technology.

What Exactly is 2K Injection Molding?

2K injection molding, also known as two-shot molding or double-injection molding, is a manufacturing process that uses a single, specialized injection molding machine to create a single part from two different thermoplastic materials. The "2K" originates from the German term Zwei Komponenten, meaning "two components."

The core of the process involves injecting a first material (the substrate) into a mold, then repositioning that newly formed part to a second cavity within the same tool, where a second material (the overmold) is injected onto or around it. Because this all happens in one continuous, automated cycle, the two materials form a powerful, permanent bond.

The technology that enables this process is Dual Material Tooling. Unlike a standard injection mold, a 2K tool is a complex piece of engineering with two distinct cavities and a mechanism to move the substrate between shots. Its precision is paramount to the success of the final part.

2K Molding vs. Overmolding vs. Insert Molding

These terms are often used interchangeably, but they describe distinct processes. Understanding the difference is crucial for selecting the right manufacturing method for your project.

| Process | Description | Key Characteristic | Best For |

| 2K Injection Molding | A single, integrated process where two plastic materials are injected sequentially in the same machine and mold. | Automated & High-Speed. The part is never handled between shots. | High-volume production of complex parts with integrated soft-touch grips, seals, or multiple colors. |

| Pick-and-Place Overmolding | A two-step process. A substrate is molded first in a standard machine. It is then manually or robotically placed into a second tool in another machine, where the second material is molded over it. | Manual or robotic transfer. Slower cycle times and potential for contamination between steps. | Lower production volumes, prototyping, or when the substrate and overmold materials require vastly different processing temperatures. |

| Insert Molding | A pre-made component, often made of metal (like a screw thread or electrical contact), is placed into the mold, and plastic is injected around it. | Incorporates non-plastic parts. The "insert" is not molded in the same process. | Creating plastic parts with integrated metal threads, pins, fasteners, or electronic components. |

Export to Sheets

In essence, 2K molding is the most efficient and integrated method for creating all-plastic, multi-material components.

What are the Primary Advantages of 2K Injection Molding?

Choosing 2K molding is a strategic decision that delivers significant returns in product quality, manufacturing efficiency, and market appeal. It moves beyond simple fabrication to become an integral part of value-driven product design.

- Improved Product Functionality & Ergonomics This is perhaps the most recognized benefit. By molding a soft, tactile thermoplastic elastomer (TPE) or thermoplastic polyurethane (TPU) onto a rigid substrate like ABS or polycarbonate (PC), you can create comfortable, non-slip grips. This is essential for power tools, surgical instruments, kitchen utensils, and any product that requires secure handling.

- Enhanced Aesthetics & Design Freedom The process allows for multi-color designs in a single part without the need for painting or printing, which can wear off over time. You can create sharp, crisp color separations for branding, indicators, or simply sophisticated visual appeal. This durability is critical for automotive interiors, consumer electronics, and high-end appliances.

- Reduced Assembly Costs & Time Every manual assembly step adds labor costs, increases cycle time, and introduces a risk of human error. 2K molding eliminates the need to bond, weld, or fasten separate components together. For products with integrated gaskets or seals, this consolidation can dramatically simplify the supply chain and production line, leading to significant cost savings at scale.

- Superior Part Quality & Durability When compatible materials are used, the two shots form a strong, permanent chemical bond at the molecular level. This is far superior to a mechanical or adhesive bond, resulting in a part that will not delaminate, peel, or separate even under stress, vibration, or exposure to chemicals. This robustness is vital for mission-critical applications in the medical and automotive industries.

- Watertight Sealing & Environmental Resistance By molding a flexible, gasket-like material directly onto a rigid housing, 2K molding can create integrated, high-performance seals. This is a perfect solution for electronic enclosures, outdoor equipment, and automotive components that need to be protected from dust, water, and other environmental factors.

How Does the 2K Injection Molding Process Work?

The elegance of 2K molding lies in its automated precision. While the concept is straightforward, the execution relies on sophisticated tooling and machinery. The process can be broken down into five key stages.

Step 1: Mold Design & Tooling Creation

The journey begins with the dual material tool. This is far more complex than a standard mold and represents the largest initial investment. The tool must have two different cavities (one for the first shot, one for the second) and a mechanism to transfer the substrate. Engineers at SunOn Mould use advanced CAD/CAM software to design these molds, ensuring perfect alignment, cooling, and material flow for both components.

Step 2: The First Shot (Substrate)

The mold closes, and the first injection unit injects the primary material—typically the rigid structure of the part—into the first cavity. This component is known as the substrate. It is held at a specific temperature and pressure to ensure it is fully formed but still receptive to the second shot.

Step 3: Mold Repositioning

This is the defining stage of the 2K process. Once the substrate is partially cooled, the mold opens slightly, and the substrate is transferred to the second cavity. There are several common methods for this transfer:

- Rotary Platen: The entire mold half attached to the moving platen of the machine rotates, typically 180 degrees, to align the substrate with the second injection nozzle. This is the fastest and most common method for high-volume production.

- Core-Back / Retractable Core: Sections of the mold core retract, creating space for the second material to be injected around the substrate. This method is suitable for simpler geometries like integrated seals.

- Shuttle Mold: Two different bottom mold halves "shuttle" back and forth to align with a single top half, moving the substrate from the first to the second station.

Step 4: The Second Shot (Overmold)

With the substrate perfectly positioned in the second cavity, the mold closes again. The second injection unit injects the second material (the overmold) into the spaces around or onto the substrate. The heat from this second shot helps to fuse the two materials together, creating a strong chemical bond if the materials are compatible.

Step 5: Cooling & Ejection

The completed, two-material part is allowed to cool within the mold until it is solid enough to be ejected. The mold opens, and an ejector pin system pushes the finished component out. The entire cycle, from the first injection to ejection, is complete, and the mold is ready for the next shot.

Which Materials Can Be Combined in 2K Molding?

The success of a 2K molded part depends entirely on the compatibility of the two materials. A poor material choice will result in delamination and part failure. The goal is to achieve a strong, permanent bond, which can be accomplished in two ways.

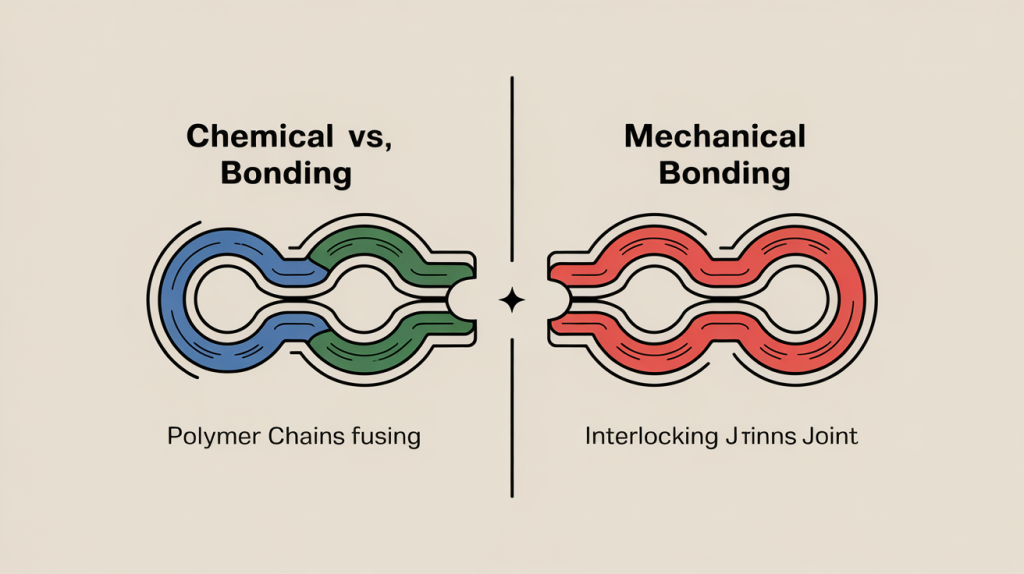

1. Chemical Bonding

This is the ideal scenario. A chemical bond occurs when the two materials are from compatible polymer families. During the second shot, the heat of the molten overmold material melts the surface of the substrate, allowing the polymer chains from both materials to intermingle and fuse at a molecular level. This creates an exceptionally strong, seamless bond that is often as strong as the materials themselves.

2. Mechanical Bonding

When a chemical bond isn't possible due to material incompatibility, a mechanical bond is required. This is achieved through clever part design. The substrate is designed with features like undercuts, grooves, holes, or rough textures that the overmold material can flow into. Once the overmold solidifies, it is physically locked onto the substrate. While not as elegant as a chemical bond, a well-designed mechanical interlock can create a very robust connection.

Material Compatibility Chart

Choosing the right pair is a critical decision. This chart provides a general guideline for common material combinations. Testing is always recommended for specific applications.

| Substrate Material (Rigid) | Compatible Overmold Material (Flexible/Soft) | Bond Type | Common Applications |

| ABS (Acrylonitrile Butadiene Styrene) | TPE-S, TPU | Chemical | Consumer electronics, appliance housings |

| PC (Polycarbonate) | TPE-S, TPU, LSR | Chemical | Power tool handles, durable electronics |

| PC/ABS Alloy | TPE-S, TPU | Chemical | Automotive interior components |

| PA6 / PA66 (Nylon) | TPE-S, TPE-V, TPU (Bondable Grades) | Chemical (with special grades) | Industrial components, demanding applications |

| PP (Polypropylene) | TPE-S, TPE-V (Bondable Grades) | Chemical (with special grades) | Household goods, flexible hinges, packaging |

| POM (Acetal / Delrin) | TPU (Some Grades) | Mechanical (Generally requires interlocks) | Gears with soft surfaces, high-wear parts |

| PBT (Polybutylene Terephthalate) | TPE-S | Chemical | Electronic connectors, sensors |

| PS (Polystyrene) | TPE-S | Chemical | Disposable items, toys |

Export to Sheets

How Should You Design Parts for 2K Injection Molding?

Effective part design is non-negotiable for successful 2K molding. The design must account for both material properties and the intricacies of the molding process. Collaborating with an experienced mold maker like SunOn Mould early in the design phase can prevent costly errors.

Here are eight critical design guidelines for dual material tooling:

- Prioritize Material Compatibility: This is the first and most important step. Consult the compatibility chart and material datasheets to ensure the chosen substrate and overmold can form a reliable bond.

- Define the Bonding Strategy: Decide upfront whether you will rely on a chemical or mechanical bond. If a mechanical bond is needed, design robust interlocking features into the substrate.

- Maintain Uniform Wall Thickness: Just like in standard molding, consistent wall thickness is key to preventing defects like sink marks, voids, and warpage. This applies to both the substrate and the overmold sections.

- Design Effective Shut-Offs: A "shut-off" is the area where the two materials meet, and the mold steel must press together to prevent the second material from flashing or "bleeding" onto unwanted areas of the substrate. This transition line should be as sharp and well-defined as possible. A gradual, feathered edge is extremely difficult to mold cleanly.

- Optimize Gate Location: The gate—where the molten plastic enters the cavity—must be placed carefully for both shots. Poor gate location can lead to cosmetic defects, weak weld lines, and incomplete filling of the part.

- Incorporate Proper Draft Angles: Both the substrate and the final part need draft angles (a slight taper on vertical walls) to ensure they can be easily ejected from the mold without damage. A minimum of 1-2 degrees is a good starting point.

- Account for Material Shrinkage: All thermoplastics shrink as they cool. The design must account for the different shrinkage rates of the two materials to avoid internal stresses and warpage in the final part.

- Ensure Smooth Material Transition: The transition between the hard substrate and the soft overmold should be smooth to avoid creating stress concentration points. Abrupt changes in geometry can lead to part failure under load.

Where is 2K Injection Molding Used?

The versatility of 2K molding has made it indispensable across a wide range of industries, enabling the creation of innovative and high-performance products.

- Automotive: Used extensively for interior components like dashboards with soft-touch surfaces, steering wheels, control knobs, and exterior parts like integrated seals on windows and lighting enclosures.

- Consumer Electronics: Essential for creating durable and ergonomic products like smartphone cases with protective bumpers, remote controls with soft buttons, and wearable tech like smartwatch bands.

- Medical Devices: Critical for applications requiring both sterility and usability, such as surgical instruments with non-slip grips, diagnostic device housings with integrated seals, and syringe plungers.

- Power Tools & Appliances: The signature soft grips on drills, saws, and sanders are a classic application of 2K molding. It's also used for kitchen utensil handles and appliance control panels.

- Packaging: Used to create advanced caps and closures with built-in, tamper-evident seals, providing superior product protection and user convenience.

Conclusion: Elevate Your Product with 2K Molding

2K injection molding is more than just a manufacturing process; it's a strategic tool for creating superior products. By consolidating parts, reducing assembly costs, and unlocking new possibilities in design and functionality, it provides a powerful competitive advantage. The process transforms a simple plastic component into an integrated, high-performance system with enhanced ergonomics, aesthetics, and durability.

Successfully leveraging this technology requires deep expertise in material science, part design, and precision toolmaking. With decades of experience and a commitment to engineering excellence, SunOn Mould is the ideal partner to bring your most ambitious product designs to life.

Ready to explore how 2K injection molding can elevate your next project? Contact our engineering team today to discuss your requirements and get a quote.

Frequently Asked Questions about 2K Molding

The primary difference is the process integration. 2K molding is a single, automated process within one machine. Standard overmolding is a two-step process, often involving manual transfer of the substrate part from one machine to another, making it slower and less suitable for high volumes.

Yes, the initial investment is higher. Dual material tooling is significantly more complex and expensive to design and build than a standard mold. The specialized injection molding machines also cost more. However, for high production volumes, this initial cost is often offset by the elimination of secondary assembly labor and improved part quality.

Lead times for 2K tools are generally longer than for single-shot tools due to their complexity. A typical lead time can range from 8 to 16 weeks, depending on the part's size, complexity, and the required testing and validation.

No. The "2K" process is specifically for combining two different plastics. The process of molding plastic around a metal component is called insert molding. While both create multi-material parts, the underlying technology and equipment are different.