What is 2K injection molding explained with process and benefits

In modern manufacturing, product developers face a persistent challenge: creating complex components that are both highly functional and aesthetically pleasing without driving up assembly costs and introducing points of failure. Traditional methods often require producing multiple individual parts and then joining them with screws, adhesives, or manual labor. This multi-step approach is slow, expensive, and can compromise the final product's integrity.

2K injection molding is an advanced manufacturing process that creates a single, complex part from two different plastic materials in one automated machine cycle, dramatically improving product quality and reducing assembly costs. It is the technology that enables the creation of seamless, integrated components that are stronger, more reliable, and offer superior design freedom.

As a world-leading specialist in high-precision tooling and injection molding, SunOn Mould leverages its deep expertise from our base in China to deliver these advanced manufacturing solutions to a global clientele. This guide explains the entire 2K molding process, its key benefits, and why it is the superior choice for your next innovative product.

What Exactly is 2K Injection Molding? (And How is it Different?)

2K injection molding, also known as two-shot, double-injection, or multi-component molding, is a highly integrated plastic manufacturing process. The "2K" is derived from the German term Zwei Komponenten, meaning "two components." It utilizes a specialized injection molding machine with two independent injection units to combine two different polymers into a single, finished part during one continuous operation.

To truly understand its value, it's essential to distinguish it from similar manufacturing processes.

| Process | Process Type | Cycle Speed | Bond Strength | Best For |

| 2K Injection Molding | Fully automated single-cycle | Very Fast | Excellent (Molecular bond) | High-volume production of complex parts with integrated seals, grips, or colors. |

| Pick-and-Place Overmolding | Two separate machine cycles | Slow | Good to Excellent | Prototyping, lower volumes, or when materials have vastly different molding temperatures. |

| Insert Molding | Single cycle with pre-made part | Fast | Excellent (Mechanical bond) | Encapsulating non-plastic parts like metal threads, magnets, or electronic circuits in plastic. |

Export to Sheets

While all three methods create multi-material parts, 2K molding offers the highest level of integration, speed, and bond quality for all-plastic components. For a more detailed analysis, you can explore our complete 2K Injection Molding Guide.

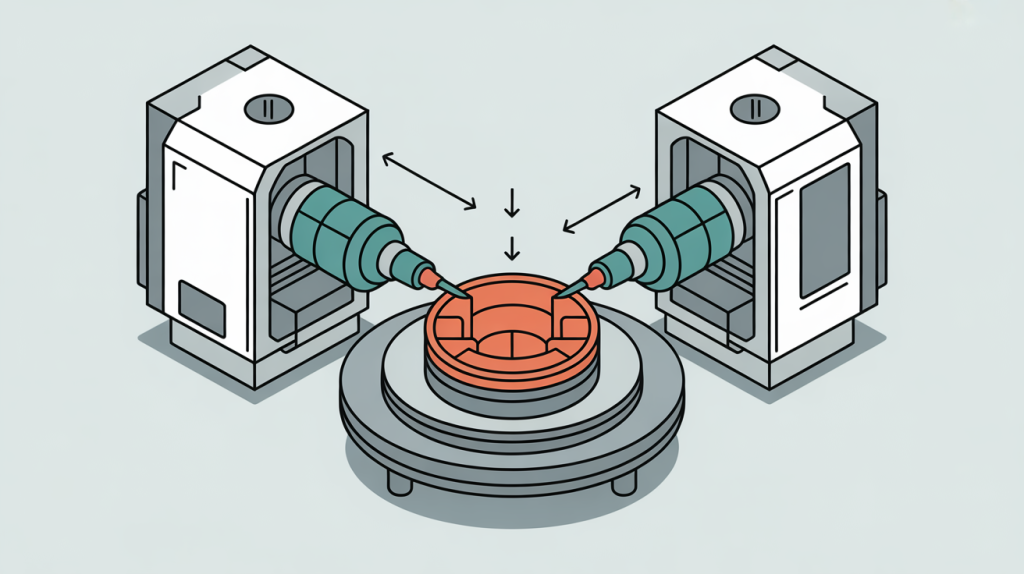

A Step-by-Step Look at the 2K Molding Process

The magic of 2K molding lies in its precision-engineered tooling and automated machine sequence. Here is a clear breakdown of how a two-material part is created from raw pellets to a finished product.

Step 1: Designing the Dual-Material Tool

It all begins with the mold. A 2K mold is a marvel of engineering, containing two distinct cavities—one for each shot—and a mechanism to move the part between them. The design must account for the shrinkage rates of both materials, precise cooling channels, and perfectly aligned shut-offs.

Step 2: The First Shot (Injecting the Substrate)

The process starts as the mold closes and the first injection unit injects the primary material (the substrate) into the first cavity. This is typically the more rigid, structural component of the part.

Step 3: The Critical Rotation (180-Degree Mold Repositioning)

Once the substrate has cooled just enough to be solid, the mold opens. The platen holding the core side of the mold rotates 180 degrees. This movement transfers the newly formed substrate from the first cavity into the second cavity, aligning it perfectly for the next injection.

Step 4: The Second Shot (Injecting the Overmold)

The mold closes again. The second injection unit then injects the second material (the overmold) into the second cavity. This molten plastic flows onto, into, and around the substrate, filling the remaining space to complete the part's geometry.

Step 5: Bonding, Cooling, and Ejection

The heat from the second shot fuses the overmold material to the substrate, creating a powerful molecular bond. The completed, two-material part then cools uniformly inside the mold. Finally, the mold opens for the last time, and ejector pins push the finished component out, ready for use with no assembly required.

The Key Benefits: Why Choose 2K Molding for Your Project?

Adopting 2K molding is a strategic decision that pays dividends in quality, efficiency, and marketability.

- Superior Durability & Reliability The molecular bond created between compatible materials is far stronger than any adhesive or mechanical fastener. The resulting part is a single, solid unit that will not peel, separate, or leak, making it ideal for high-stress applications and sealed enclosures.

- Enhanced Ergonomics & Aesthetics This process allows for the combination of hard and soft polymers seamlessly. This is the technology behind the durable, comfortable handles on high-end products. (Learn more about manufacturing soft touch grips with 2K molding). Furthermore, it allows for creating multi-color parts with crisp separation lines for branding or functional indicators, which are far more durable than paint or labels.

- Reduced Assembly Costs By consolidating what would have been two or more components into a single part, 2K molding completely eliminates the need for downstream assembly labor, screws, clips, and adhesives. For high-volume production, this translates directly into significant cost savings per unit.

- Supply Chain Simplification Fewer individual parts means a simpler Bill of Materials (BOM), less inventory to manage, and a more streamlined supply chain. This reduces logistical complexity and potential delays.

- Improved Part Quality & Precision Because the entire part is created within a single tool, the tolerance and alignment between the two materials are exceptionally precise, far exceeding what is possible with manual assembly. This leads to higher overall consistency and quality.

Material Compatibility: The Secret to a Perfect Bond

The success of any 2K molding project hinges on selecting two materials that can bond effectively. There are two primary bonding methods:

- Chemical Bond: This is the ideal scenario, where the two polymer families are chemically compatible. The heat from the second shot melts the surface of the first, allowing the polymer chains of both materials to entangle and fuse as they cool. This creates a powerful, permanent bond at the molecular level.

- Mechanical Bond: When materials are not chemically compatible, a strong connection can be achieved through clever part design. The substrate is designed with features like holes, grooves, or undercuts that the overmold material flows into, creating a physical interlock that holds the two parts together.

Common Material Compatibility Chart

| Substrate (Rigid) | Overmold (Soft/Flexible) | Bond Type |

| PP (Polypropylene) | TPE (Thermoplastic Elastomer) | Chemical |

| ABS (Acrylonitrile Butadiene Styrene) | TPU (Thermoplastic Polyurethane) | Chemical |

| PC (Polycarbonate) | TPE, TPU, LSR | Chemical |

| PA (Nylon) | TPE (Bondable Grades) | Chemical |

| POM (Acetal) | Most TPEs / TPUs | Mechanical |

Export to Sheets

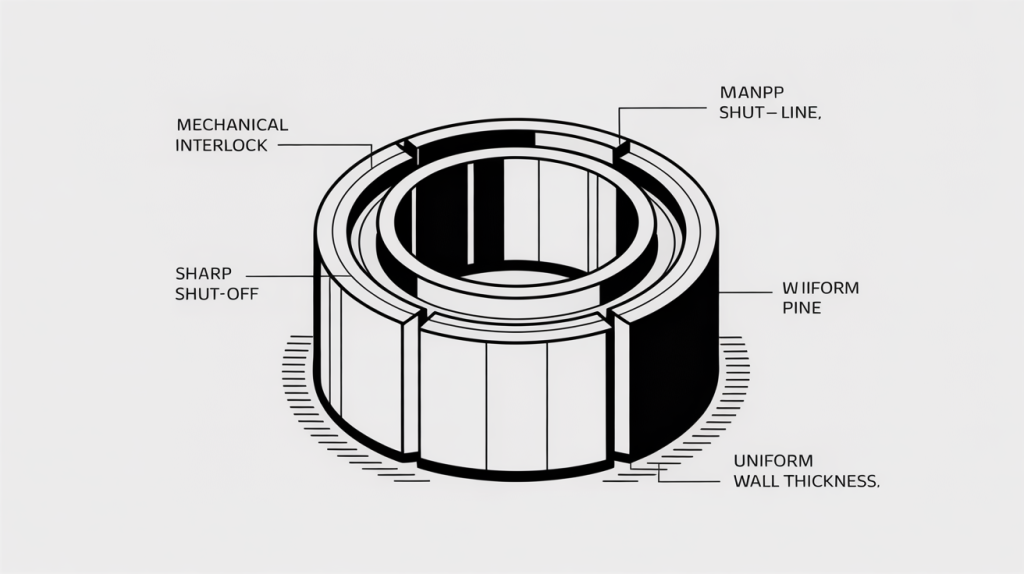

10 Critical Design Rules for Engineers

Designing for 2K injection molding requires a deeper level of consideration than standard molding. Following these design-for-manufacturing (DFM) principles is essential for a successful outcome.

- Prioritize Material Selection: Always start by choosing your two materials based on their chemical compatibility and the physical requirements of your application.

- Design Robust Mechanical Interlocks: Even with chemically compatible materials, designing in subtle mechanical interlocks provides a fail-safe, ensuring the strongest possible bond.

- Maintain Uniform Wall Thickness: Both the substrate and the overmold sections should have consistent wall thicknesses to prevent defects like sink marks, voids, and warpage.

- Create Sharp, Well-Defined Shut-Offs: The line where the hard and soft materials meet must be a crisp, clean step. This allows the mold to seal off perfectly, preventing the overmold material from "flashing" or bleeding.

- Use Textured Surfaces for Better Adhesion: Applying a light texture to the substrate surface area that will be overmolded increases the surface area and can significantly improve bond strength.

- Incorporate Generous Radii: Avoid sharp internal corners where the two materials meet. Smooth, rounded transitions (radii) help distribute stress and prevent potential cracking.

- Optimize Gate Locations: Carefully plan the injection points (gates) for both materials to ensure smooth filling of the cavity and to hide any cosmetic blemishes on non-visible surfaces.

- Ensure Proper Mold Venting: Trapped air is the enemy of a perfect part. The mold must be designed with adequate vents to allow air to escape as the molten plastic rushes in.

- Account for Differential Shrinkage: The two different materials will shrink at different rates as they cool. Your design and the mold's cooling system must account for this to prevent internal stress and warping.

- Consult Your Manufacturer Early: Engage with an experienced 2K molding partner like SunOn Mould early in the design process. Our engineering feedback can save you time, money, and costly redesigns down the line.

Global Sourcing, Local Expertise: Why Partner with a China-Based 2K Molding Specialist

In a globalized economy, sourcing decisions are critical to a project's success. China stands as the world's undisputed leader in advanced manufacturing, offering a unique combination of technological prowess, massive scale, and deep supply chain integration. For companies looking to leverage complex processes like 2K injection molding, partnering with a specialist in China provides distinct advantages.

This ecosystem allows an experienced partner like SunOn Mould to provide world-class services with unmatched efficiency. We offer international clients the benefits of:

- Advanced Technology & Economies of Scale: Access to state-of-the-art machinery and a mature supply chain results in higher precision and more competitive pricing.

- Proven Export Quality: Operating under rigorous ISO 9001 quality management standards, we have a proven track record of delivering components that meet or exceed the expectations of clients in North America, Europe, and beyond.

- End-to-End Project Management: Our teams are experts in managing the entire production process for international clients, from initial design consultation and tool manufacturing to quality control and global logistics.

Conclusion: A Superior Process for a Superior Product

2K injection molding is a transformative technology that bridges the gap between complex design and efficient manufacturing. It empowers companies to create products that are more durable, ergonomic, and visually striking, all while simplifying the production process and reducing long-term costs. It is the key to building a better product from the inside out.

Realizing the full potential of this process requires a partner with deep technical knowledge, state-of-the-art facilities, and a global mindset.

Ready to bring next-generation quality and performance to your products? Contact SunOn Mould’s global engineering team today to discuss your 2K injection molding project and receive a comprehensive quote.

Frequently Asked Questions

The most common applications include automotive interior components (buttons, knobs), power tool handles, medical device grips, consumer electronics with integrated seals or soft-touch features, and kitchen utensils.

No, 2K molding is a process for combining two different plastics. The process of molding plastic around a pre-made metal component is a different technology called insert molding.

Yes. Due to the complexity of having two cavities and a rotation mechanism, a 2K mold is significantly more expensive to design and build than a standard single-shot mold. However, for high-volume production, these costs are often recovered through the elimination of assembly labor.

The lead time is primarily driven by the creation of the complex tool. Depending on the part's intricacy, a typical project can take anywhere from 8 to 16 weeks from design finalization to the first production run.