2K Injection Mould (Dual-Color Injection) – A Complete Guide

Introduction to 2K Injection Mould (Dual-Color Injection)

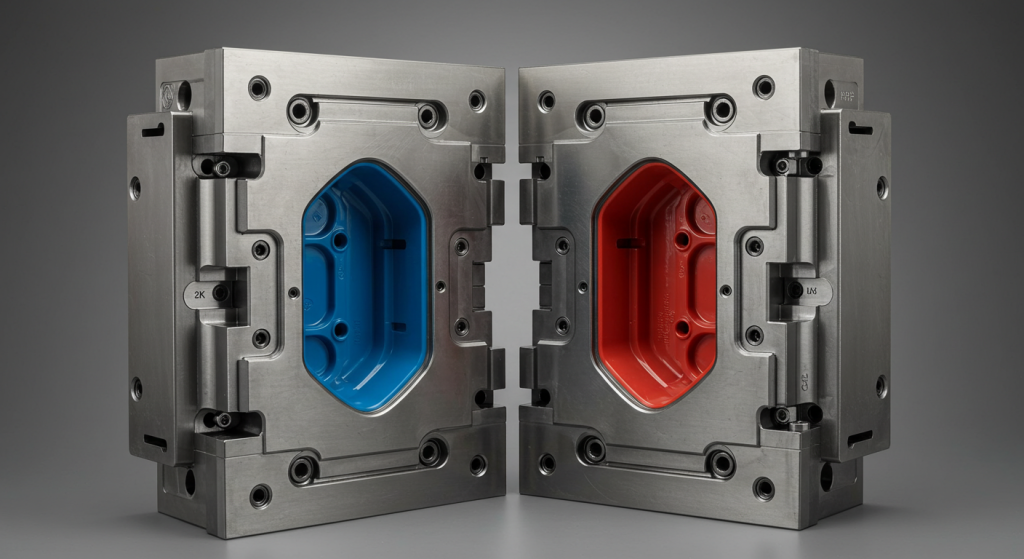

The 2k injection mould (dual-color injection) is a quickly growing demand in the sphere of contemporary manufacturing. This new procedure enables the producers to produce multifaceted, heavy, and aesthetically appealing components with two diverse materials or colours in one moulding process. In contrast to traditional techniques, two-shot injection molding combines several materials in a way that makes them seamless, saves the time spent on their assembly, and increases the functionality of the product.

What is a 2K Injection Mould?

Dual-color injection moulding or two-shot injection molding. Two materials are injected into a single mould to produce one component in a 2K injection mould, also called a dual-color injection mould. Such materials may vary in:

- Color (for visual appeal)

- Soft-touch overmolding (hardness)

- Functionality (rigid + flexible combinations)

It is a more efficient method, which adds value and beauty to the product and reduces secondary operations.

What is the Mechanism of Dual-Color Injection?

The dual-shot is a process of molding that uses two units of injection in series:

1. First Shot - This is the injection of the primary structure base material.

2. Second Shot - A secondary material (in a different color or property) becomes injected into the same mould where it bonds with the initial one.

This is done by using high-precision tooling to inject the material in dual colors so as to achieve flawless alignment and bonding.

Benefits of 2K Injection Moulding

The application of 2K moulding technology has several advantages:

No Adhesives or Assembly - No adhesives or assembly.

Durability - Makes powerful, durable parts.

Flexibility of Design - Allows multi-color and multi-material design.

Cost Savings - Lowers production processes and labor expenses.

Better Performance - Soft-touch grips, waterproof seals, and ergonomic components.

2K Injection Mould Dual-Color, Dual-Material Innovation

2K injection mould is a new technology applicable in two-component (2-shot) injection molding. It allows creating one, combined part, into which two different substances or colors are injected at different stages into the same mould. This procedure provides smooth bonding that also does not require adhesives or any form of secondary assembly.

With the mix of such materials as TPU + ABS, PC + PC, or soft + hard plastics, the manufacturers can create both visually appealing and useful components that are durable at the same time. The uses are soft-touch grips, a two-color logo, waterproof seals, ergonomics, and high-performance parts.

Flawless Integration of High-Performance

The primary benefit of dual-shot molding is that it enables the provision of smooth integration of materials. By using a single mould and process, manufacturers have high-efficiency production, shorter turnaround, and minimal operational cost. The multi-component injection molding process, with precision and consistent outcome, is guaranteed even in mass production.

The high-technology method finds extensive application in the automotive components, consumer electronics, medical devices, and industrial equipment markets, where durability and looks are equally considered.

Experience in the Molding of High-performance

SunOn Industrial Group offers complete solutions in plastic injection and die-casting moulds. From design and engineering up to manufacturing, mass production, assembly, and packaging, SunOn assists clients in simplifying production, minimizing risks, and controlling costs.

Knowing how to make custom 2K injection moulds, SunOn achieves precision tooling, material matching, and scalability in both small and large production quantities. SunOn can deliver prototypes, dual-material consumer products, and large-scale industrial solutions with reliability, innovation, and speed.

Uses of 2K Injection Mould

The highly injected multi-component industries are:

1. Automotive Industry

• The automotive 2K injection moulding finds extensive application in dashboards, switches, handles, and lighting systems.

• Dual-color injection increases safety and attractiveness.

2. Medical Devices

Multi-shot moulding of medical devices. Ergonomic and sterile-friendly designs can be achieved by multi-shot moulding.

• Ex: soft-touch grips on surgical tools.

3. Consumer Electronics

Two-shot moulds of consumer electronics permit smooth designs featuring dual color finishes.

• Ordinarily found in smartphone cases, keypads, and bracelets.

4. Industrial Products

Industrial plastic overmolding assists in making robust and resistant components for heavy usage.

5. Household Goods

There is soft-touch overmolding of consumer goods, such as toothbrushes and kitchen utensils.

Technical Data and Process Insights

The most prominent technical points about 2K injection moulding are:

- Tolerance Range: Precise moulds are guaranteed to have tolerances in microns.

- Material Bonding: Thermoplastics such as ABS + TPE are usually applied.

- Cycle Time: Dual-color injection can be a little bit longer, but it substitutes several production steps.

- Tooling Design: This involves sophisticated 2K mould design, rotary platen, or rotary core.

- Volume Production: Suitable for prototype to production solutions as well as large-scale.

2K Injection Mould (Dual-Color Injection) Cost

2K injection moulds cost depending on:

• Complexity of design

• Number of cavities

• Material selection

• Production volume

The tooling will be more expensive, but the low-cost 2K moulding system will improve the long-term costs by removing assembly costs.

Future-Ready and Sustainable Solutions

The contemporary industries are emphasizing injection moulding materials that are sustainable. Eco-friendly plastics can be used in combination with recyclable materials with 2K moulding technology. This not only enhances the performance of the products but also lessens the impact on the environment.

Conclusion

Industries are being remodelled as the 2K injection mould (dual-color injection) process continues to be precise, efficient, and flexible. It can be dual-colour injection moulds in the consumer electronics or 2K injection moulds used in the automotive components, but the possibilities are unlimited. Multi-color injection molding combined with co-injection molding technology and plastic overmolding solutions will enable businesses to have durable, cost-effective, and appealing products. At SunOn, we think that we offer novel moulding solutions that empower industries throughout the world. The future of the manufacturing industry is dual shot, and 2K injection moulding is at its center stage.