Aerospace Silicone Seals and Gaskets High Performance

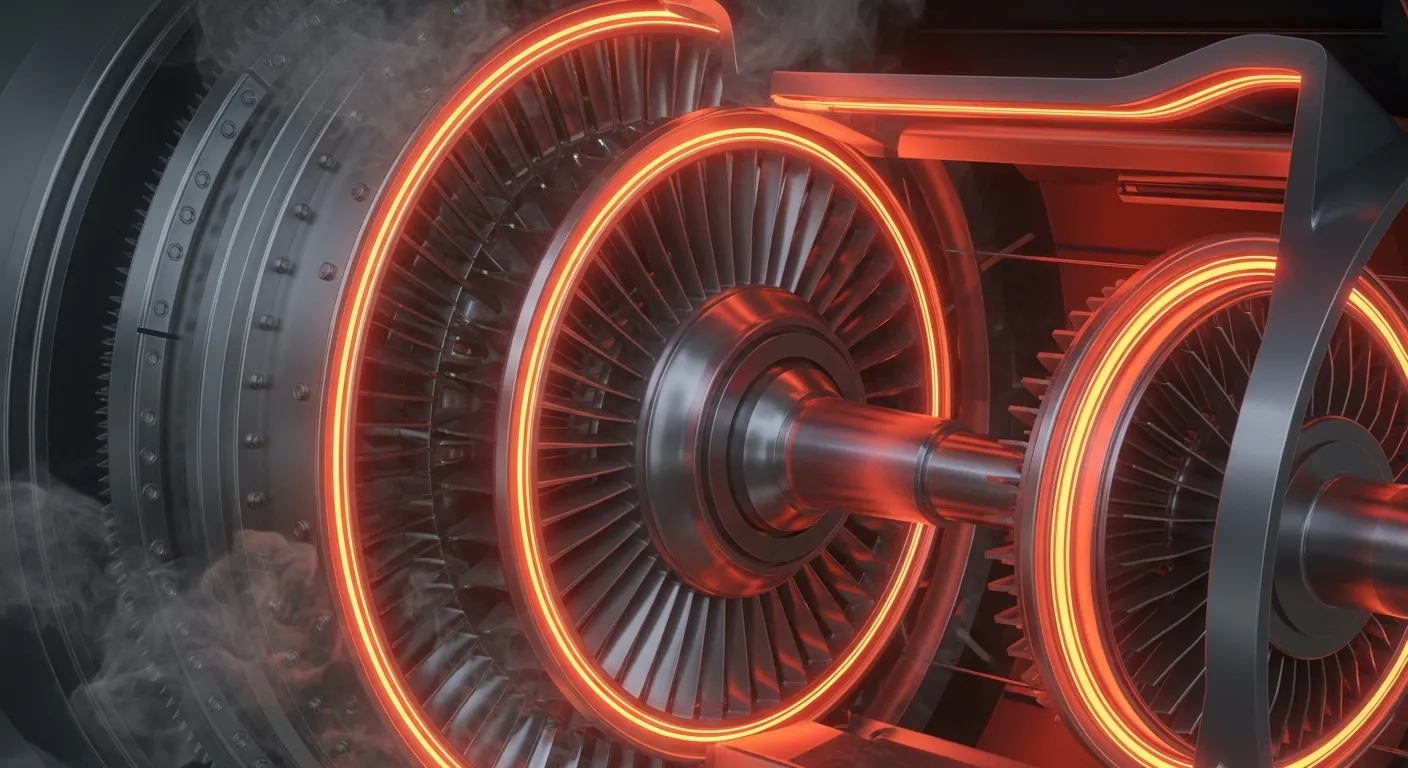

Aerospace silicone seals and gaskets provide high-performance sealing solutions for extreme aviation environments. These components are critical for maintaining pressure, preventing leaks, and protecting sensitive electronics in aircraft systems. Unlike standard rubber, aerospace-grade silicone maintains its flexibility and structural integrity across a vast temperature range, typically from -60°C to +230°C (or higher with specialized additives). They are engineered to resist UV radiation, ozone, and various aviation fluids while meeting stringent safety standards for flame retardancy and low smoke toxicity. Because flight safety depends on component reliability, high-performance silicone is the industry standard for ensuring airtight enclosures in engines, cabins, and fuel systems.

Why is Aerospace Silicone Used for High-Performance Seals?

In the aerospace industry, "high performance" isn't just a buzzword—it’s a survival requirement. Aircraft transition from scorching tarmac temperatures to the freezing altitudes of the stratosphere in minutes. Standard materials would become brittle or melt under these conditions.

Aerospace silicone is preferred because of its molecular stability. It provides a reliable seal that prevents the loss of cabin pressure and protects jet engines from environmental contaminants. This reliability is why manufacturers also utilize precision silicone parts for tight tolerance applications to ensure every seal fits perfectly within complex assemblies.

What are the Main Types of Aerospace Gaskets?

Aerospace gaskets are generally categorized by their specific function and the environment they inhabit:

- Static Seals: Used where there is no movement between mating surfaces, such as fuel tank access panels.

- Dynamic Seals: Designed for moving parts, such as hydraulic actuators or landing gear components.

- EMI/RFI Shielding Gaskets: Specialized silicone infused with conductive particles to protect flight deck electronics silicone parts from electromagnetic interference.

- Environmental Seals: Protect against moisture, dust, and rain in external housings.

What is the temperature range for aerospace silicone seals?

Aerospace silicone seals typically operate effectively between -62°C and +232°C (-80°F to +450°F). This wide range allows them to remain elastic at high altitudes and heat-resistant near engines.

While standard silicone handles these ranges well, "Fluorosilicone" is often used when the seal also needs to resist jet fuel and petroleum-based oils. This chemical resistance ensures that the seal does not swell or degrade when exposed to harsh chemicals.

How long do silicone gaskets last in aircraft?

The lifespan of an aerospace silicone gasket varies based on its application, but they are generally designed for long-term durability, often lasting between 10 to 20 years. Regular maintenance checks and environmental exposure (such as high UV or chemical contact) will dictate the specific replacement cycle.

To maximize longevity, engineers prioritize high-tear strength formulations. This prevents the gasket from ripping during installation or under the high-vibration conditions common in flight.

Material Comparison: Silicone vs. Fluorosilicone vs. EPDM

Choosing the right material is vital for safety and performance. Here is how aerospace-grade silicone compares to other common elastomers:

| Feature | Silicone (VMQ) | Fluorosilicone (FVMQ) | EPDM |

| Temp Range | Excellent (-60 to +230°C) | Excellent (-60 to +200°C) | Good (-50 to +150°C) |

| Fuel Resistance | Poor | Excellent | Poor |

| Ozone Resistance | Excellent | Excellent | Excellent |

| Best Use Case | Cabin seals, ducting | Fuel systems, engines | Window seals, hydraulics |

Key Performance Requirements for Aviation Gaskets

For a gasket to be flight-ready, it must adhere to several industry certifications:

- BMS (Boeing Material Specifications): Often requires specific fire-resistant properties.

- AMS (Aerospace Material Specifications): Sets the standard for physical and chemical properties.

- Low Outgassing: Vital for space applications and sensitive optical equipment to prevent lens fogging.

Beyond aerospace, these high standards often influence other sectors. For instance, the hygiene standards required in medical silicone rubber components mirror the material purity needed in advanced aviation sensors.

Frequently Asked Questions

Yes, but they are typically used in the "cool" sections of the engine or for external accessories. In the highest-heat zones, specialized fluorocarbon or metal seals may be required.

Most aerospace-grade silicones are formulated to be self-extinguishing and meet FAR 25.853 regulations regarding flame, smoke, and toxicity (FST).

Aerospace seals undergo much more rigorous testing for pressure changes and extreme cold. However, the durability of automotive silicone rubber parts often draws from aerospace technology to improve vehicle longevity.

Compression set occurs when a gasket loses its ability to "spring back." Using high-quality post-cured silicone and ensuring proper groove design can significantly reduce this risk.

Key Takeaways

- Extreme Versatility: Silicone remains flexible from -60°C to +230°C.

- Safety First: Aviation seals must meet strict FST (Fire, Smoke, Toxicity) standards.

- Material Selection: Use Fluorosilicone for fuel contact and standard Silicone for environmental sealing.

- Precision Matters: Tight tolerances are essential to maintain cabin pressure and protect electronics.

Conclusion

Aerospace silicone seals and gaskets are the unsung heroes of aviation safety. By providing high-performance sealing under the most grueling conditions on Earth (and above it), these components ensure that aircraft remain pressurized, powered, and protected. Whether you are designing for commercial jets or defense systems, choosing the right material grade is the difference between a successful mission and a mechanical failure.