Custom Automotive Silicone Rubber Parts and Sealing Components

Automotive silicone rubber parts and sealing components provide critical protection against extreme temperatures, aggressive fluids, and environmental contaminants in modern vehicle systems. These high-performance elastomers are essential for ensuring the longevity of internal combustion engines (ICE) and the safety of high-voltage electric vehicle (EV) battery packs.

By reading this guide, you will:

- Control material selection by identifying when to use LSR vs. HCR or FVMQ.

- Master quality standards required for IATF 16949 and ISO 3302-1 compliance.

- Optimize for EV safety with UL 94-V0 and IP68 sealing strategies.

- Reduce manufacturing risks by avoiding common design and material pitfalls.

Essential Automotive Sealing Components: From Engines to EVs

Modern automotive engineering demands sealing solutions that remain flexible from -60°C up to 300°C (needs verification). Silicone rubber is the preferred material for these environments due to its low compression set and excellent ozone resistance.

Key components include:

- Engine Gaskets & O-Rings: Rocker cover gaskets and oil filter seals that withstand constant thermal cycling.

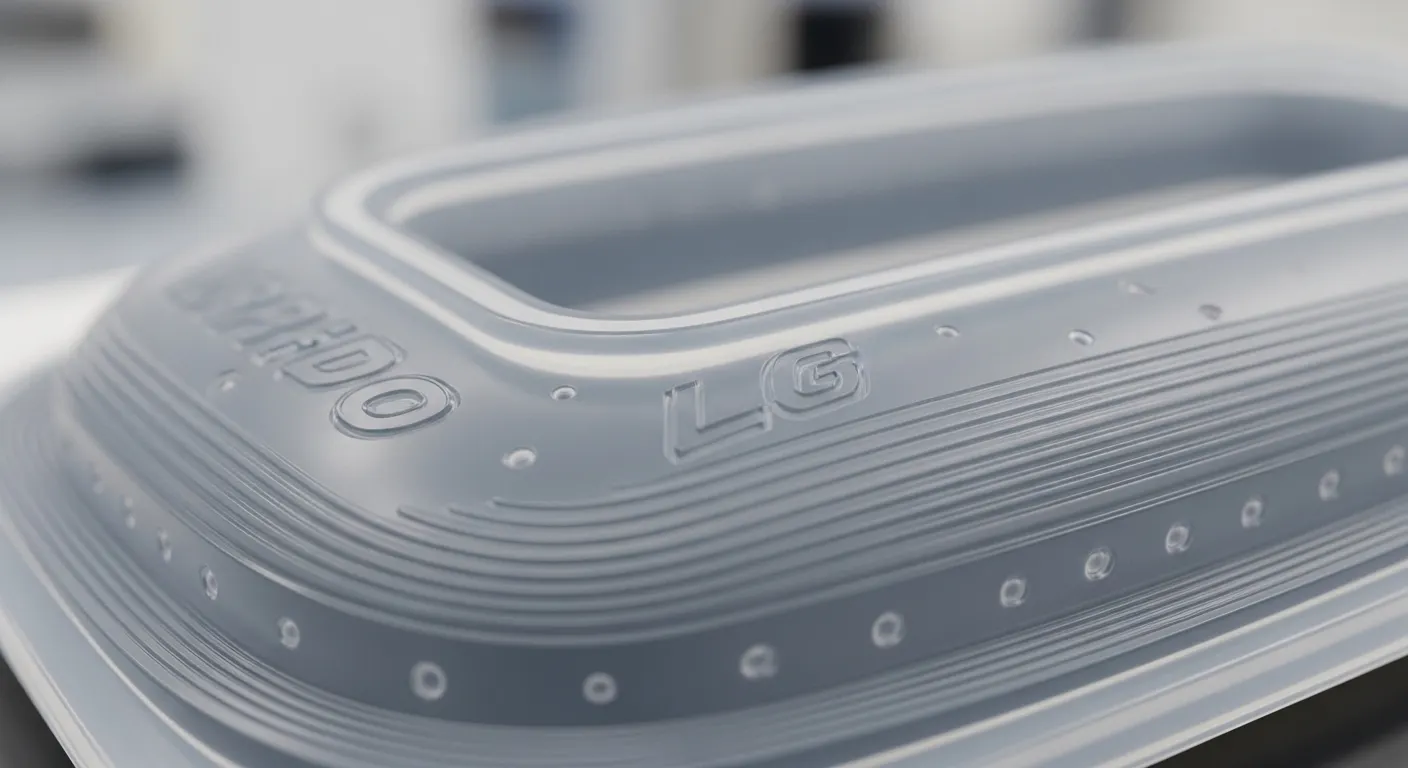

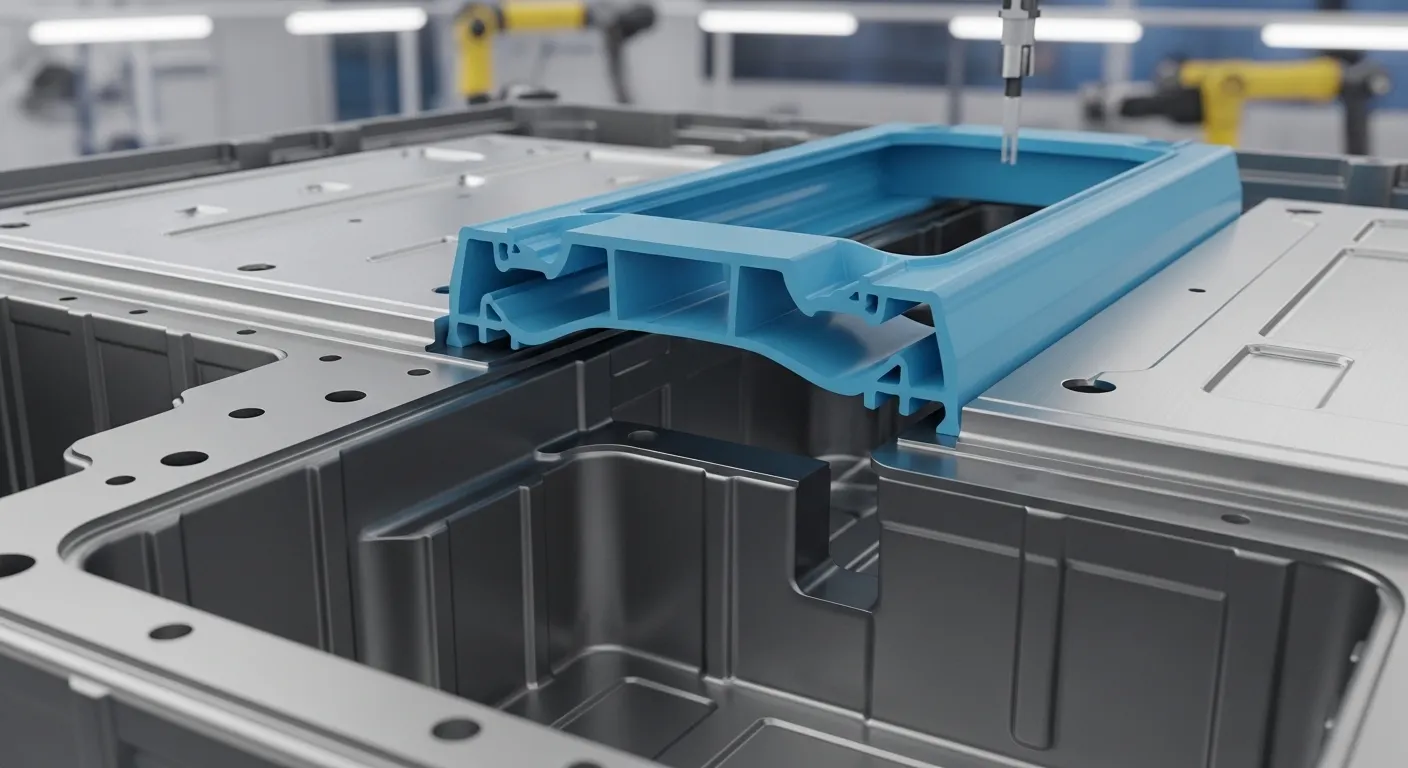

- EV Battery Seals: Large-perimeter gaskets for battery enclosures that prevent moisture ingress.

- Electrical Protection: Spark plug boots, wiring harness grommets, and connector seals.

- Vibration Damping: Specialized mounts that isolate sensitive sensors from road noise and mechanical shock.

For example, self-bleeding silicone connectors are often utilized in moisture-proof wiring to provide a permanent barrier against water wicking. When designing these parts, engineers often leverage our precision silicone parts for tight tolerance applications to ensure a perfect fit in compact assemblies.

Material Selection: LSR vs. HCR and Specialty Compounds

Choosing the right silicone grade is the most critical step in the custom silicone rubber parts manufacturing process.

Liquid Silicone Rubber (LSR) for High-Precision

LSR is a two-component system processed via injection molding. It is ideal for high-volume, complex geometries because of its low viscosity, which allows it to fill intricate mold cavities with minimal flash. This "flash-less" molding reduces secondary trimming costs and ensures higher consistency for safety-critical parts.

High Consistency Rubber (HCR)

Also known as solid silicone, HCR is a gum-like material typically processed through compression molding or extrusion. It generally offers higher tensile strength and is more cost-effective for larger, simpler parts like hoses or large flat gaskets.

Fluorosilicone (FVMQ) for Fuel & Oil Resistance

Standard silicone (VMQ) swells when exposed to gasoline or low-molecular-weight aromatic hydrocarbons. In these environments, FVMQ is used. By adding fluorine to the molecular chain, FVMQ maintains silicone’s temperature resistance while providing significantly better chemical stability.

Common Mistake to Avoid: Never specify standard VMQ for components in direct contact with fuel or aggressive engine oils. Use FVMQ to prevent premature seal failure and swelling.

Manufacturing Standards & Quality (IATF 16949)

In the automotive sector, quality management is governed by the IATF 16949 standard. This requires a robust system for risk management, defect prevention, and supply chain traceability.

Dimensional accuracy is verified using ISO 3302-1. For precision automotive molding, parts are typically held to:

- Class M1 (Very Fine): Requires expensive, high-precision tooling and strict environmental controls.

- Class M2 (Fine): The standard for high-quality automotive seals and technical moldings.

If your project also requires metal housings or structural components, understanding how to choose between zinc and aluminum die casting can help you coordinate the entire assembly's thermal expansion and sealing requirements.

Sealing Solutions for Electric Vehicle (EV) Batteries

As the industry shifts toward electrification, sealing requirements have evolved to focus on Thermal Management and Ingress Protection.

EV battery enclosures must meet:

- IP67/IP68 Ratings: Ensuring the battery remains functional even after temporary immersion in water.

- UL 94-V0 Flame Retardancy: This standard measures the material's ability to self-extinguish. Silicone is inherently flame-resistant, but EV grades are often enhanced with intumescent additives to delay thermal runaway propagation.

- EMI Shielding: Conductive silicone gaskets protect sensitive battery management systems (BMS) from electromagnetic interference.

Using silicone in EV applications also provides superior vibration damping compared to traditional EPDM or polyurethanes. This is particularly important for the longevity of high-voltage cells. For other automotive structural needs, consider the advantages of zinc die casting for automotive parts to complement your silicone sealing strategy.

FAQ: Automotive Silicone & Sealing Components

Fluorosilicone (FVMQ) is best for engine areas exposed to fuel and oil, while high-temperature Liquid Silicone Rubber (LSR) is ideal for coolant seals and electrical connectors.

Yes. Silicone gaskets, especially those formed-in-place (FIPG) or precision-molded to Class M2 tolerances, are capable of meeting IP68 ratings for deep-water immersion.

Standard automotive silicone typically operates from -60°C to +230°C, though specialized grades can reach +300°C for short periods.

LSR is better for high-volume, complex parts requiring tight tolerances and automated production. HCR is often preferred for larger, simpler gaskets or extruded hoses.

It is a fire safety rating indicating that the material stops burning within 10 seconds on a vertical specimen; it is mandatory for battery housing components to prevent fire spread.

Standard silicone (VMQ) will swell and lose structural integrity in mineral oils. FVMQ (Fluorosilicone) should be used if oil resistance is required.

Conclusion

Automotive silicone rubber parts are indispensable for the next generation of vehicle design. Whether you are solving for the high-heat environment of a turbocharged engine or the stringent safety requirements of an EV battery pack, selecting the correct material and manufacturing process is vital.

Ready to optimize your sealing components? Contact Sunon-mould today for a DFM (Design for Manufacturing) review of your automotive silicone parts.