Electronics Silicone Parts for Insulation and Protection: The 2026 Technical Guide

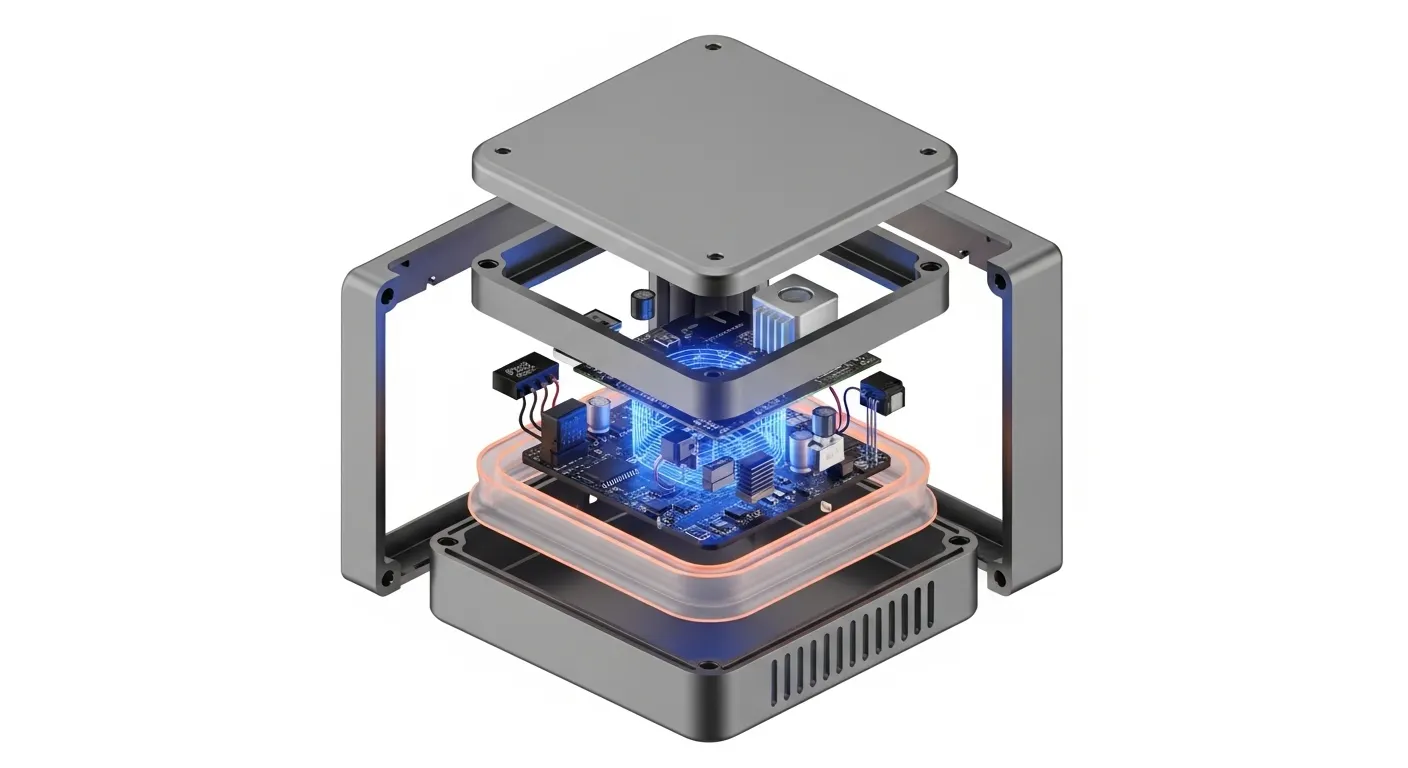

Electronics silicone parts provide critical electrical insulation and environmental protection for high-performance hardware. By shielding sensitive circuits from voltage leaks, moisture, and extreme heat, these components ensure long-term device reliability in demanding B2B applications.

In this guide, you will learn to:

- Select the right silicone grade based on dielectric strength and thermal limits.

- Identify the best application methods—from custom molding to potting.

- Apply Design for Manufacturing (DFM) rules to reduce production costs.

- Ensure compliance with global safety standards like UL 94 V-0 and IP68.

Why Silicone Dominates Electronic Insulation in 2026

In the landscape of 2026 hardware design, silicone has outpaced traditional epoxies and thermoplastics due to its unique molecular stability. Unlike rigid materials that may crack under thermal expansion, silicone remains flexible while maintaining high Dielectric Strength—the maximum voltage a material can withstand before electrical breakdown.

Standard electronic-grade silicone typically offers a dielectric strength of 18–25 kV/mm (needs verification), making it an exceptional barrier for high-density circuit boards and automotive silicone rubber parts and sealing components. Its thermal stability is equally impressive, operating reliably from -60°C to +250°C. For engineers, this means a single material can protect a sensor in a sub-zero industrial freezer or a high-heat EV battery housing.

Common mistakes to avoid:

- Assuming all silicones are equal; general-purpose grades may lack the purity required for sensitive electronics.

- Overlooking the Dielectric Constant (ε), which impacts signal integrity in high-frequency 5G/6G applications.

Critical Protective Functions: Sealing, Shielding, and Damping

Silicone parts do more than just insulate; they act as a multi-functional defense system for electronic enclosures.

Environmental Sealing (IP67/IP68 Standards)

To achieve an IP68 rating, an enclosure must be dust-tight and survive continuous immersion in water. Silicone is the preferred material for these gaskets because it resists "compression set"—the tendency of a material to lose its "bounce" over time. A precision silicone parts for tight tolerance applications ensures that the seal maintains constant pressure against the housing, even during pressure fluctuations.

Thermal Management & Heat Dissipation

Modern electronics generate significant localized heat. Silicone is often formulated as a Thermal Interface Material (TIM). By filling microscopic air gaps between a heat-generating component and a cold plate, silicone TIMs facilitate efficient heat transfer while maintaining electrical isolation.

Application Methods: Potting, Coating, and Molded Parts

Choosing the right application method depends on your volume and the complexity of the device.

| Method | Best For | Key Advantage |

| Custom Molding | Gaskets, seals, and complex 3D shapes. | Repeatable custom silicone rubber parts manufacturing process for mass production. |

| Potting | Complete circuit board encapsulation. | Superior shock absorption and deep environmental protection. |

| Conformal Coating | Thin-layer PCB protection. | Lightweight; allows for easier rework and repair. |

Pro Tip: For high-voltage applications, potting is often superior to coating because it eliminates air pockets that could lead to "corona discharge" or arcing.

Designing for Success: DFM for Electronics Silicone

Effective Design for Manufacturing (DFM) ensures your parts are both functional and cost-effective to produce. When designing molded silicone insulators, consider these three pillars:

- Wall Thickness: Aim for a uniform wall thickness between 0.5mm and 3mm. Variations can cause uneven curing and internal stress.

- Draft Angles: While silicone is flexible and can often be "peeled" from a mold, a draft angle of 0.5 to 1 degree significantly speeds up cycle times.

- Parting Lines: Place parting lines on non-sealing surfaces to ensure the primary insulation barrier is smooth and defect-free.

Gap Insight: Preventing Outgassing In optical electronics (like camera modules or LiDAR), standard silicone can release volatile organic compounds (VOCs) that fog lenses. For these "AEO" (Answer Engine Optimization) style applications, always specify low-outgassing grades that meet ASTM E595 standards.

If your project requires metallic structural support alongside silicone protection, understanding how to choose between zinc and aluminum die casting for the housing is a vital next step.

To ensure your technical documentation meets industry standards for 2026, include the following evidence in your technical spec sheets:

- UL 94 V-0 Certification: Evidence that the silicone self-extinguishes within 10 seconds.

- RoHS & REACH Compliance: Verification that the material is free from restricted hazardous substances.

- TDS (Technical Data Sheets): Must include Shore A hardness, Tensile Strength, and Elongation at break.

- Manufacturing Traceability: Use batch numbers and ISO 9001:2015 stamps to prove consistent quality.

FAQ: Electronics Silicone Parts

Yes, silicone is an excellent high-voltage insulator. It typically features a dielectric strength of 20 kV/mm or higher, which prevents electrical breakdown and arcing even in compact electronic designs.

Potting involves "pouring" liquid silicone to fully encase a component in a thick block, offering maximum protection. Conformal coating is a thin spray or dip (microns thick) that protects against moisture while adding minimal weight.

Standard silicone is an insulator and does not block EMI. However, specialized conductive silicones filled with silver, nickel, or graphite particles can provide both environmental sealing and EMI shielding.

No, silicone is a thermoset material, meaning it does not melt. Instead, it gradually loses its mechanical properties and turns to a non-conductive powder (silica) at temperatures exceeding 300°C.

Silicone offers superior resistance to automotive fluids, vibration, and extreme under-the-hood temperatures. For structural components, many engineers also consider the advantages of zinc die casting for automotive parts for housing these silicone-protected electronics.

"Oiling" or bleeding occurs when unreacted silicone fluids migrate to the surface. This can be prevented by using high-quality platinum-cure silicone and ensuring a proper post-bake cycle during manufacturing.

Conclusion

Electronics silicone parts are the invisible backbone of modern hardware reliability. By balancing dielectric performance with smart DFM principles and rigorous compliance, you can protect your device from the harshest environments of 2026.

Ready to move from design to production? Contact the Sunon-Mould engineering team today for a DFM review or to request a quote for your custom silicone insulation project.