How 2K injection molding works step by step

Creating robust, integrated, multi-material components without cumbersome and costly assembly steps is one of modern manufacturing's greatest challenges. Traditionally, achieving a product with both a rigid structure and a soft, ergonomic grip meant producing separate parts and then bonding them together—a process that introduces time, expense, and potential points of failure. But what if you could create a single, seamless part in one elegant step?

2K injection molding works by first injecting a plastic substrate into a mold, then automatically repositioning it to a second cavity within the same tool, where a second, compatible plastic is injected over it—all in a single, highly efficient machine cycle. This sophisticated process eliminates the need for post-production assembly, resulting in a stronger, more reliable, and cosmetically superior component.

As a global leader in precision 2K molding, SunOn Mould operates advanced manufacturing facilities in both China and the USA. This unique footprint allows us to provide world-class engineering and logistics to a diverse international clientele. In this guide, we will break down exactly how this transformative technology works, step by step.

The Technology Behind the Process: What Equipment is Required?

Before diving into the steps, it's crucial to understand that 2K injection molding is not a standard process that can be performed on any machine. It requires a significant investment in specialized technology, which is fundamental to its success.

- The Specialized 2K Molding Machine: Unlike a standard injection molding machine that has a single injection unit, a 2K machine is equipped with two independent injection units. Each unit has its own barrel, screw, and nozzle, allowing it to melt and inject a different thermoplastic material simultaneously or in a controlled sequence.

- The Complex Dual-Material Tool: The mold is the true heart of the process. A 2K mold is a complex piece of precision engineering containing two unique cavities—one for the initial part (the substrate) and one for the final, combined part. It also incorporates a sophisticated mechanism, most commonly a rotary platen, to transfer the substrate from the first cavity to the second with micron-level accuracy. The design and construction of this tool are critical and represent a significant portion of the initial project investment. For a deeper dive into the overall technology, you can explore our complete 2K Injection Molding Guide.

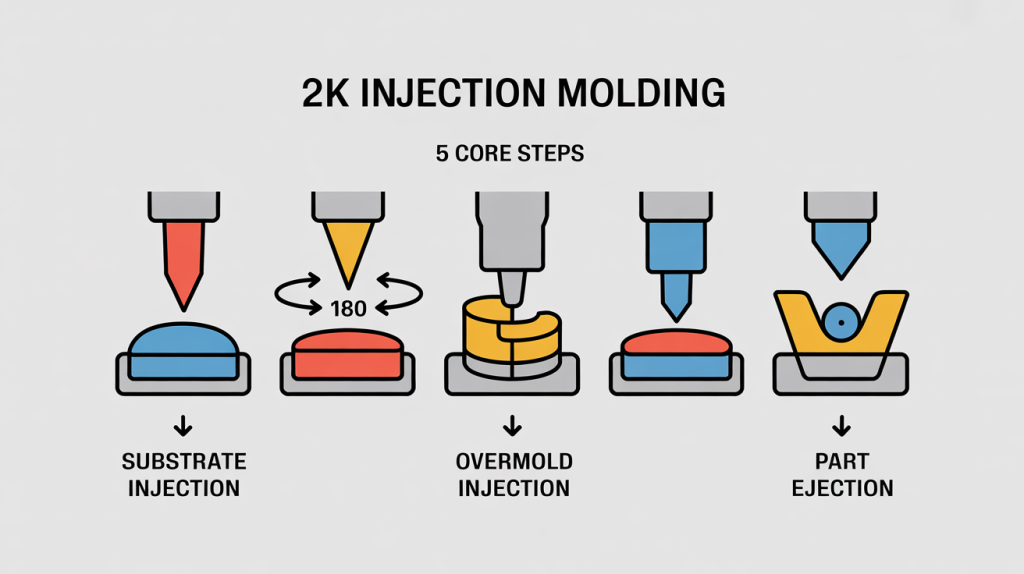

How 2K Injection Molding Works: The 5 Core Steps

The 2K injection molding cycle is a marvel of automation and precision. While it happens in a matter of seconds, it can be broken down into five distinct and critical stages.

Step 1: Tooling, Material, and Machine Setup (The Blueprint)

Before the first part is ever produced, a meticulous setup phase occurs. The heavy, complex dual-material tool is installed in the 2K molding machine. Both thermoplastic materials, which have been selected for their chemical compatibility and physical properties, are loaded into separate hoppers and dried to the precise moisture content required. Our engineers then program the machine with the exact parameters for the project—injection speeds, pressures, melt temperatures, and cooling times for both materials. This blueprint ensures consistency and quality from the first part to the last.

Step 2: The First Injection (Creating the Substrate)

The cycle officially begins. The mold closes, and the first injection unit injects molten plastic into the first cavity. This shot forms the substrate, which is typically the rigid, structural foundation of the component. The machine holds this part under pressure for a set time, allowing it to cool just enough to become solid and stable for the next step.

Step 3: The Transfer (The Key Movement)

This is the defining mechanical action of the 2K process. The mold opens slightly, and the core-half of the tool, holding the newly formed substrate, rotates 180 degrees. This movement perfectly aligns the substrate within the second, larger cavity of the mold. While the rotary platen is the most common and fastest method for high-volume production, other techniques exist:

- Core-Back: A section of the mold core retracts, creating a new space for the second material without rotation. This is often used for creating integrated seals or layers.

- Shuttle Mold: Two separate lower mold halves "shuttle" back and forth to align with a single upper half, moving the substrate between stations.

Step 4: The Second Injection (Overmolding & Molecular Bonding)

With the substrate securely in place, the mold closes again. The second injection unit now injects the second material—often a soft TPE for grips or a different color for aesthetics—into the second cavity. This molten plastic flows over, into, and around the substrate. The intense heat from this second shot melts the surface of the substrate, allowing the polymer chains of both materials to intertwine, forming a permanent, unbreakable molecular bond as they cool.

Step 5: Cooling & Ejection (The Finished Part)

The newly formed, two-material component is held in the closed mold for a final cooling period. This ensures the part is dimensionally stable and the bond is fully set. Once the cooling time elapses, the mold opens, and an ejector system pushes the finished part out, ready for use. The entire cycle, from the first injection to ejection, is complete, and the machine is immediately ready to begin the next.

Beyond the Steps: What Critical Parameters Ensure Quality?

Following the five steps is only part of the story. Consistent, high-quality production relies on the precise control of numerous process parameters. At SunOn Mould, our engineers fine-tune these variables to achieve flawless results.

- Temperature Control: We control both the melt temperature of each plastic and the temperature of the mold itself through complex cooling channels. Incorrect temperatures can lead to a weak bond, cosmetic defects, or part warpage.

- Injection Pressure & Speed: The speed and pressure at which the plastic is injected determine how the material flows into the cavity. These must be optimized to ensure the part is completely filled without creating flash (excess material leaking from the mold).

- Cooling Time: If a part is ejected before it has cooled sufficiently, it can warp or shrink unpredictably. The cooling time is calculated based on the material type, part thickness, and mold temperature to ensure dimensional stability.

What Happens When the Process Goes Wrong? (Common Defects & Solutions)

Because 2K molding is a complex process with many variables, a deep understanding of potential defects is crucial for any high-quality manufacturer. This expertise allows for rapid troubleshooting and process optimization.

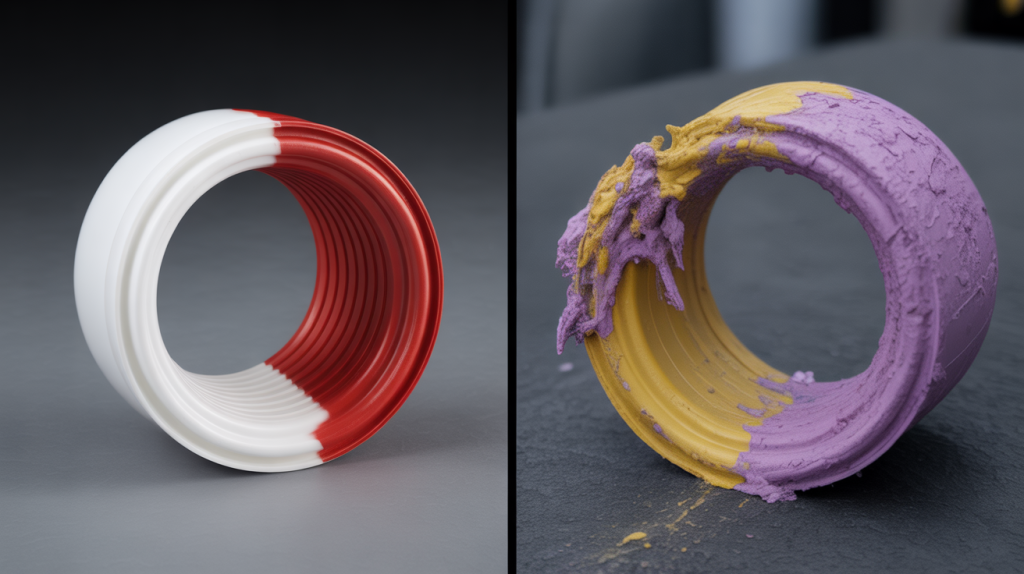

| Defect | Common Cause(s) | Expert Solution |

| Flash (Material Bleed) | The mold is not sealing properly ("shutting off"); injection pressure is too high. | Re-machine the tool for a perfect seal; optimize the injection pressure and speed profile. |

| Delamination (Poor Bond) | Materials are not chemically compatible; melt temperature is too low. | Verify material compatibility; increase melt temperature to ensure proper surface melting of the substrate. |

| Short Shot (Incomplete Part) | Injection pressure is too low; the mold is not venting properly, trapping air. | Increase injection pressure or speed; clean and verify the mold's air vents to allow trapped gas to escape. |

Understanding the 2k injection molding process benefits and its potential pitfalls is key to leveraging it effectively.

A Global Advantage: Why Partner with a China/USA Manufacturer?

For global companies developing cutting-edge products, the choice of a manufacturing partner is a critical strategic decision. A partner with a presence in both China and the USA, like SunOn Mould, offers a unique and powerful advantage.

- Leveraging China's Manufacturing Power: Our state-of-the-art facility in China provides access to the world's most mature and cost-effective manufacturing ecosystem. This is ideal for high-volume production where economies of scale are paramount, allowing our clients to achieve a competitive price point without sacrificing quality.

- Leveraging USA's Market Proximity: Our US-based facility offers distinct advantages for our North American clients. It facilitates faster logistics, provides localized engineering support for real-time collaboration, and is essential for projects that may have domestic supply chain requirements or ITAR considerations.

This dual-footprint model provides ultimate flexibility. Our clients can choose the optimal manufacturing location based on their project's specific needs for cost, speed-to-market, and logistical convenience. It's a global solution tailored to the demands of modern product development, especially for complex components like soft touch grips.

Conclusion

The 2K injection molding process is a precise, multi-stage operation that represents the pinnacle of modern manufacturing efficiency. It transforms two separate materials into a single, integrated component with superior strength, function, and aesthetics. Understanding how it works reveals a process where success is measured in microns and milliseconds, requiring a deep level of expertise in tooling, material science, and process control.

When expertly executed, this technology moves beyond simple production to become a true competitive advantage.

Whether your project demands the scale of our China facility or the strategic location of our US plant, our team is ready to deliver. Contact us today to put our global 2K molding expertise to work for you.

Frequently Asked Questions

The cycle time varies depending on the size and complexity of the part, but it is generally very fast, often ranging from 30 to 60 seconds for a complete, two-material part.

Typically, the more rigid, structural material (the substrate) is injected first. It needs to be stable enough to withstand the pressure of the second injection without deforming.

Yes. While less common, the same principles can be extended to 3K (three-shot) or even 4K molding, allowing for the creation of components with even greater complexity, such as a part with a rigid core, a soft grip, and a clear window.

The process is controlled by the precision of the mold. The crisp "shut-off" lines machined into the steel tool create a perfect seal against the substrate, preventing the second material from bleeding or mixing with the first and ensuring a sharp, clean transition.