Low-Volume CNC parts Machining Services: Durable & Accurate

What is Low Volume CNC Parts Machining?

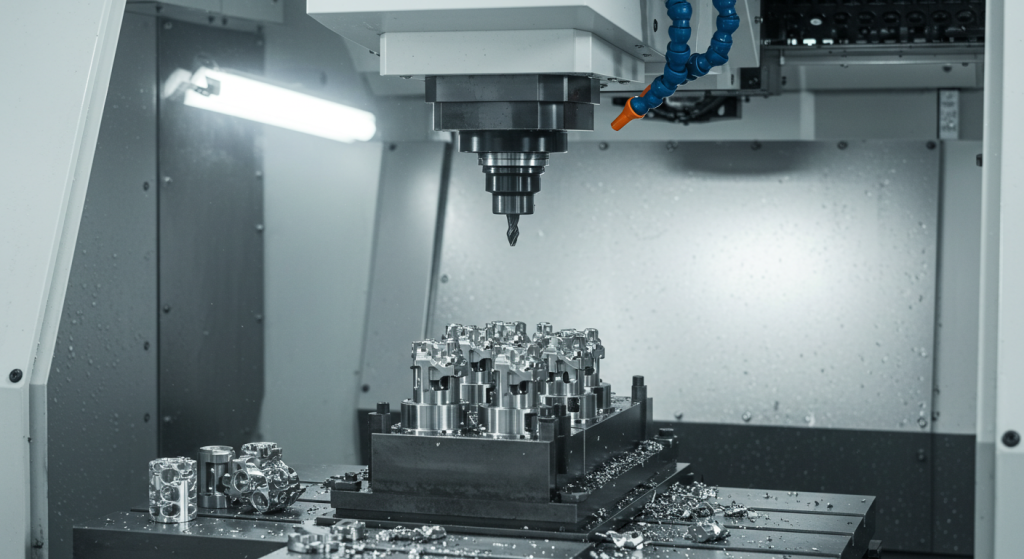

Low-volume CNC machining Low volume CNC machining involves the manufacture of fewer than 50 custom-fabricated parts using computer-controlled milling, turning, and drilling equipment. In contrast to large-scale production, it is short-run production or production, usually between 1 and 100 units. Key features include:

- Excelling levels of accuracy with tolerances of +-0.01 mm to +-0.1 mm.

- Quick functional testing.

- Material choice, from aluminum to engineering plastics.

- Patient with fast turnover, suited to bridge building before large-scale production.

This method is also effective in the development of prototypes, low-volume replacement items, or custom components whose components would be expensive to make using traditional injection molding or stamping.

Low-Volume CNC Parts Machining: High Precision Production

CNC parts machining Low-volume machining CNC parts machining has transformed prototype and small-volume manufacturing. It enables companies to manufacture quality parts without incurring the massive cost incurred in mass production. CNC machining has proven to be accurate, repeatable, and has a rapid turnaround, whether it is a prototype of an automotive device or a medical device. We are SunOn Industrial Group, where we focus on providing cost-effective, flexible, and accurate low-volume CNC parts machining services.

From Design to Production

At SunOn Industrial Group, we provide a full CNC machining service, including start-to-end consultation of the design and design-to-manufacturability analysis (DFM) to prototyping and mass manufacturing. Our team of seasoned engineers cooperates with clients so that each component is of high precision yet is cost-effective and efficient.

- 3D Design & DFM Review

We start by developing a high-resolution 3D model of your part and reviewing the DFM. This step will examine the part structure in terms of manufacturability, determine the possible obstacles, and streamline the design for CNC processing efficiency.

- Material Selection

Choosing the appropriate material is of immense importance regarding performance and longevity. Our metals and plastics are numerous: aluminum, steel, brass, and engineering plastics, adapted to your project needs.

- Programming & Setup

Our engineers produce programmed CNC code and prepare machines to perform automated, accurate operations. This provides uniformity and repeatability of all parts.

- Machining Operations

We carry out milling, turning, drilling, tapping, etc., to form the part to a precise set of specifications.

- Surface Treatment

Lastly, we use finishing techniques, which include anodizing, plating, polishing, or coating, to increase durability, looks, and performance. From concept to finished part, our integrated approach ensures rapid turnaround, accurate outcomes, and dependable quality for prototypes and production batches.

Benefits of the Low-Volume CNC Machining

Cost-Effective Production

- No costly tooling and molds.

- Best when there are short-run production and prototyping functions.

Fast Turnaround

- Cycles of production are reduced compared to the conventional approaches.

- Enhances the speedy cycle of design validation.

Material Flexibility

- Metal: Aluminum, Stainless steel, Titanium, Brass.

- Plastics: ABS, Nylon, PEEK, Polycarbonate.

- Enables the performance testing of the various materials.

High Precision and Accuracy

- Keeps very small tolerances dimensionally accurate.

- Optimized with small functional parts.

Individual Design Implementation

- Powers complicated geometries up to 3-axis or 5-axis CNC machining.

- Can be used with complex prototypes and undercuts.

Uses in Industries

CNC machining of low volumes is common in industries that require precision, flexibility, and small-volume batches of high quality.

Automotive

- Prototyped gears, housings, and sensor mounts.

- Replacement components are custom-made.

Medical Devices

- Small-batch surgical tools.

- Sterilizable and durable plastic casing.

Aerospace

- Small volume, low-volume aerospace constituents.

- Testing structural prototypes.

Consumer Electronics

- Enclosures and casings of a small batch.

- Functional prototype assemblies.

Industrial Equipment

- Machine parts of low volume.

- Very durable replacement parts.

Low-Volume CNC Parts Machining Materials

The performance, durability, and low cost are factors that require the selection of the appropriate material.

Metals

- Aluminum: Lightweight, resistant to corrosion, good for use in prototypes.

- Stainless Steel: Strong, wear-resistant, and can be used as functional components.

- Titanium: Aerospace- A strong-to-weight ratio is needed.

Plastics

- ABS: Strong, simple to machine, best for prototypes.

- PEEK: High-temperature performance in high-demand applications.

- Polycarbonate/Nylon: Impact-resistant functional components.

These materials will make sure low-volume CNC parts can be produced to achieve the desired mechanical and functional requirements.

CNC Machining Techniques

Low-volume CNC machining takes advantage of the situation and utilizes advanced technologies to attain accuracy and tolerance.

3-Axis CNC Machining

- Standard flat or moderately complex parts milling.

- Simple functional prototyping (ideal)

5-Axis CNC Machining

- Deals with tricky geometries, curves, and undercuts.

- Lessens the time of manual finishing and assembly.

Turning and Milling

- Cuts and rotates cylindrical or irregular shapes.

- Allows multi-feature parts in one setup.

Drilling and Tapping

- Adds threaded holes, bores, and cavities of complexity.

- Has close tolerances even in low-volume production.

Best Practices in Low-Volume CNC Parts

Material Selection

Select materials that address mechanical and thermal requirements.

Design for CNC Machining

Streamline the geometry of parts to make them easy to produce.

Do not have excessively thin walls or deep undercuts on their own.

Quality Assurance

We have quality assurance procedures at SunOn Industrial Group:

- Pre-machining inspection of materials.

- Measurement in process with a coordinate measuring machine (CMM).

- Ultimate dimensional verification and finish.

There are certifications such as ISO 9001, IATF 16949, which guarantee the high standards of all parts.

Low-Volume CNC Parts Machining Advantages

- Quick Prototyping: Rushed product development.

- Cost Savings: Saves on excessive tooling.

- High Accuracy: Tolerances and finish.

- Material Versatility: Metals and plastics in many possibilities.

- Customizable: Accommodates complex designs and small batches.

Conclusion

CNC parts machining in low volume is a powerful, versatile, and economical solution to small-volume production, functional prototyping,g and bridge production. It enables firms in the automotive, aerospace, medical, consumer electronics, and industrial equipment industries to test designs, make highly reliable parts, and speed up time-to-market. To get high-precision, high-speed, and high-quality CNC machining services, consider SunOn Industrial Group and empower your prototype and small-volume manufacturing power now.