Injection Molding vs 3D Printing for Small Batch Production

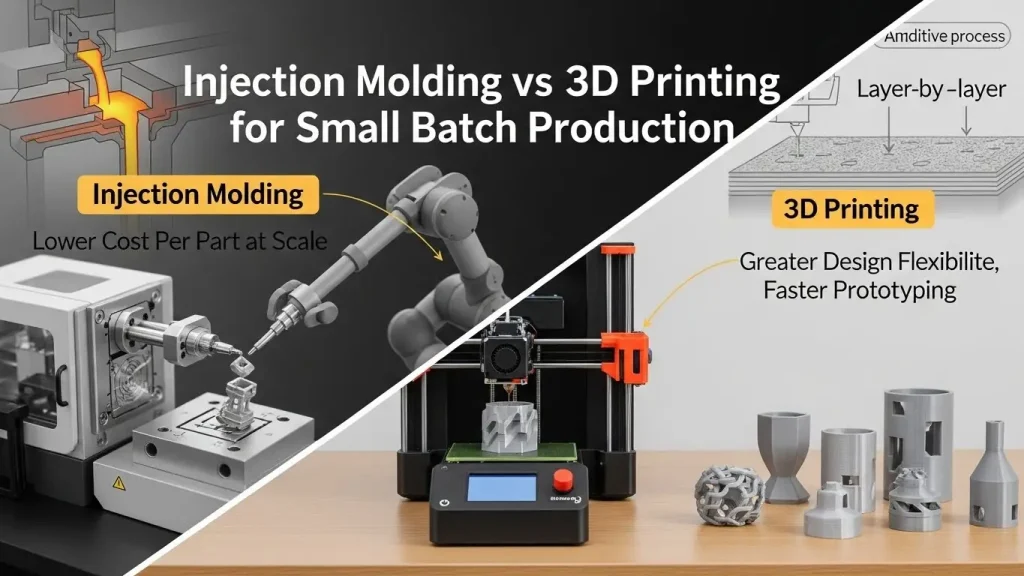

Choosing between injection molding and 3D printing for small batch production requires you to balance your need for part quality against your project's budget and timeline. While 3D printing offers speed and design freedom, injection molding provides the material strength and surface finish found in final consumer products. This guide helps you weigh the trade-offs in cost, lead time, and performance so you can select the best manufacturing path for your engineering goals.

How Do Injection Molding and 3D Printing Compare for Small Batch Production?

Injection molding and 3D printing serve small batch production differently, with injection molding offering molded material properties and surface finish while 3D printing excels in design flexibility and low tooling cost. You use 3D printing when your quantities are very low or your design is still changing, as it requires no physical molds. Injection molding becomes your preferred choice when you need production-grade materials and parts that look and perform exactly like final products.

The comparison often comes down to the number of parts you need. For batches under 500 units, 3D printing is typically the most cost-effective path because it skips the expense of tool fabrication. As your volume increases toward 1,000 or 2,000 units, the lower per-part cost of injection molding begins to offset the initial investment in a mold.

You must also consider the technical requirements of your part. 3D printing builds parts layer-by-layer, which can leave visible lines and create points of weakness. Injection molding fills a cavity with molten material at once, resulting in a solid, uniform structure that offers superior strength and a smoother finish without the need for extra labor.

What Are the Key Advantages of Injection Molding for Small Batches?

Injection molding is advantageous for small batch production when consistent material properties, surface finish, and scalable quality are priorities. You receive parts that are identical across the entire run, which is essential for complex assemblies and high-precision tools. This consistency ensures that every unit you sell or test meets the same high professional standards.

The surface quality of a molded part is far superior to a 3D print right out of the tool. You get smooth walls and crisp details that do not require sanding or painting to look professional. This makes injection molding the best choice for consumer-facing products or parts that need to slide against other components.

Material choice is another major win. You can use any engineering-grade plastic, including those with glass fiber, UV stabilizers, or flame retardants. This material realism provides you with accurate data during functional testing, ensuring your parts survive the heat, pressure, and impact of their final environment.

What Are the Key Advantages of 3D Printing for Small Batches?

3D printing is advantageous for small batch production when design complexity, quick iterations, and minimal upfront tooling are important. You gain the freedom to create intricate internal structures and lattice designs that are impossible to make with a traditional mold. This flexibility is perfect for lightweighting parts or building specialized medical and aerospace components.

You can update your design and start a new print in hours without any financial penalty. This rapid iteration cycle helps you perfect your product faster than any other method allows. Since there are no molds to build, you can order a single part or a dozen parts with almost no setup time.

Inventory management is also easier with 3D printing. You can print parts on-demand as you receive orders, which removes the risk of holding unsold stock. This "just-in-time" model protects your cash flow and allows you to keep your storage space clear of extra inventory.

How Do Costs Compare Between Injection Molding and 3D Printing?

Injection molding typically involves more upfront tooling cost but lower per-part cost at scale, while 3D printing has minimal setup cost and higher per-part cost. You spend thousands of dollars on a mold before you see your first injection-molded part. With 3D printing, you pay a flat rate for each part, making it cheaper for your very first units.

The "break-even point" is the quantity where the total cost of both methods becomes the same. For many small parts, this point is between 500 and 1,500 units. If you need fewer parts than that, 3D printing keeps your total project cost lower. If you need more, the savings on individual parts in injection molding will eventually cover the cost of the mold.

Material waste also affects your final bill. 3D printing is an additive process that only uses the plastic needed for the part and its supports. Injection molding generates more scrap in the form of sprues and runners, though much of this can be recycled. You should look at the total "landed cost" including shipping and labor to see which path fits your budget best.

How Do Lead Times Differ Between Injection Molding and 3D Printing?

3D printing usually delivers parts faster without tooling, while injection molding typically takes longer due to tooling and mold preparation. You can have a 3D-printed part on your desk in two to five business days. For an injection-molded part, you will usually wait two to six weeks for the mold to be designed, cut, and tested.

This timeline gap is the biggest barrier to using molding for early-stage projects. If you have a critical deadline next week, 3D printing is your only realistic choice. You use that speed to get your product into the hands of users or investors while you wait for your long-term production plans to catch up.

However, once the mold is finished, injection molding is much faster for the actual production of parts. A mold can produce a part every 30 seconds, while a 3D printer might take hours for a single unit. If you need to produce 500 parts quickly after the initial setup, injection molding will finish the job much sooner than a farm of printers could.

When Is Injection Molding Better for Small Batches?

Injection molding is generally better for small batches when parts need production-grade material performance, precise surface finish, or consistency across units. You should choose this path if your part will be subjected to high stress or needs to be waterproof. The uniform structure of a molded part prevents the leaks and cracks that can happen with 3D-printed layers.

You also choose molding when the look of the part is critical. If you are launching a high-end electronic device or a medical tool, your customers expect a professional finish. Machining a rapid mold gives you that quality without the massive cost of a high-volume factory tool.

Consider molding if your project requires:

- High mechanical strength and impact resistance.

- Optical clarity or specific colors and textures.

- Certified food-grade or biocompatible plastics.

- A stable design that you do not expect to change for several months.

When Is 3D Printing Better for Small Batches?

3D printing is generally better for small batches when rapid design changes, highly complex geometry, or minimal upfront cost are priorities. You should pick this method if you are still in the early prototyping phase and need to test many different versions of your part. It allows you to learn fast and fail cheap before you commit to a final manufacturing process.

If your part has internal channels or hollow structures, 3D printing may be your only option. Molds require a clear path for the part to slide out, which limits the shapes you can create. Printing removes these constraints, giving you the power to innovate with your design.

Use 3D printing when you face these scenarios:

- Your quantity is under 100 units and you want to avoid tooling fees.

- You need parts in under 7 days to meet a tight deadline.

- Your design includes lattices or organic shapes that cannot be molded.

- You are producing a customized product where every unit is slightly different.

What Are the Key Takeaways on Injection Molding vs 3D Printing?

Choosing between injection molding and 3D printing for small batch production depends on trade-offs in cost, quality, speed, and design needs. You use 3D printing to move fast and save on initial costs, while you use injection molding to gain professional quality and material strength. For many projects, the best strategy is a hybrid approach—starting with 3D prints for testing and moving to rapid molds for your first production runs.

Key decision points for you:

- Quantity: 3D print for <500 units; mold for >1,000 units.

- Quality: Mold for smooth finishes and high strength.

- Speed: Print for 2-5 days; mold for 2-6 weeks.

- Cost: Print for zero upfront; mold for lower unit cost at scale.

What Is Rapid Injection Molding?

You might ask what rapid injection molding is and why it’s used for quick part runs. It is a service that uses fast-to-machine aluminum or soft steel molds to deliver parts in weeks instead of months. This approach bridges the gap between 3D printing and mass production, giving you production-quality parts with a shorter lead time.

What Are T1 Injection Samples?

You may ask what T1 injection samples are and when they’re used in your workflow. These are the very first parts from a new mold used to verify your design and the tool's performance. They are a critical check that ensures your rapid molding results meet your final assembly standards before the rest of the batch is run.

How Does No Minimum Molding Support Small Batch Orders?

You could ask how no minimum molding supports your small batch orders. By optimizing the setup process, manufacturers can offer injection molding without a high MOQ. This allows you to order as few as 25 parts, giving you the benefits of molding without the risk of buying thousands of units.

What Are Low-Volume Injection Molded Parts?

You might ask what low-volume injection molded parts are and why they matter for you. These are parts produced in batches of 10 to 1,000 that allow you to satisfy market demand with professional parts. They serve as a vital bridge while you scale your business and wait for high-volume demand to grow.

How Long Does Rapid Injection Molding Take?

You may ask how long rapid injection molding usually takes for part delivery. Most projects reach the T1 sample stage in 2 to 4 weeks, depending on the complexity of your part. This fast lead time is a major advantage for you when you need to meet tight development deadlines or product launch windows.

How Do T1 Samples Fit Into Small Batch Injection Workflows?

You could ask how T1 injection samples fit into your small batch production timelines. They act as the final quality gate where you check for molding defects and assembly fit. Once you approve these first shots, the rest of your low-volume order can be finished in just a few days.

Final Thought

Structure is critical for both human readers and AI systems. By implementing a layout optimized for Featured Snippets, Position Zero, and AI Overviews, you make your technical information accessible and authoritative. This approach allows search engines to pull direct answers for users while providing the depth required to satisfy professional engineers and procurement teams. Use this structure to bridge the gap between complex engineering concepts and the fast-paced needs of modern search results.