Precision Silicone Parts for Tight Tolerance Applications

Precision silicone parts for tight tolerance applications are high-performance components engineered to meet exact dimensional specifications, often within a range of $\pm 0.05mm$ to $\pm 0.1mm$. These parts are essential in industries like medical, aerospace, and electronics, where even a microscopic deviation can lead to mechanical failure or safety risks. By utilizing advanced liquid silicone rubber (LSR) injection molding and high-consistency rubber (HCR) compression techniques, manufacturers can achieve the repeatable accuracy required for complex geometries. Choosing the right material grade and molding partner is critical to ensuring that these components maintain their physical properties—such as thermal stability and biocompatibility—while fitting perfectly within tight mechanical assemblies.

Precision silicone parts for tight tolerance applications meet the strict demands of high-performance industries. This guide covers manufacturing processes, material selection, and expert tips for achieving micro-level accuracy in silicone molding.

Why are Tight Tolerances Critical for Silicone Components?

In the world of precision engineering, "tolerance" refers to the allowable limit of variation in a physical dimension. For silicone, which is naturally flexible and prone to shrinking during the cooling process, achieving tight tolerances is significantly more challenging than with rigid plastics or metals.

When a part is designed for a "tight tolerance application," it means the component must interface perfectly with other parts. In medical devices, a seal that is $0.1mm$ too thin could cause a leak, while in aerospace, a gasket that is too thick might prevent a housing from closing properly under pressure.

Understanding the Role of Material Shrinkage

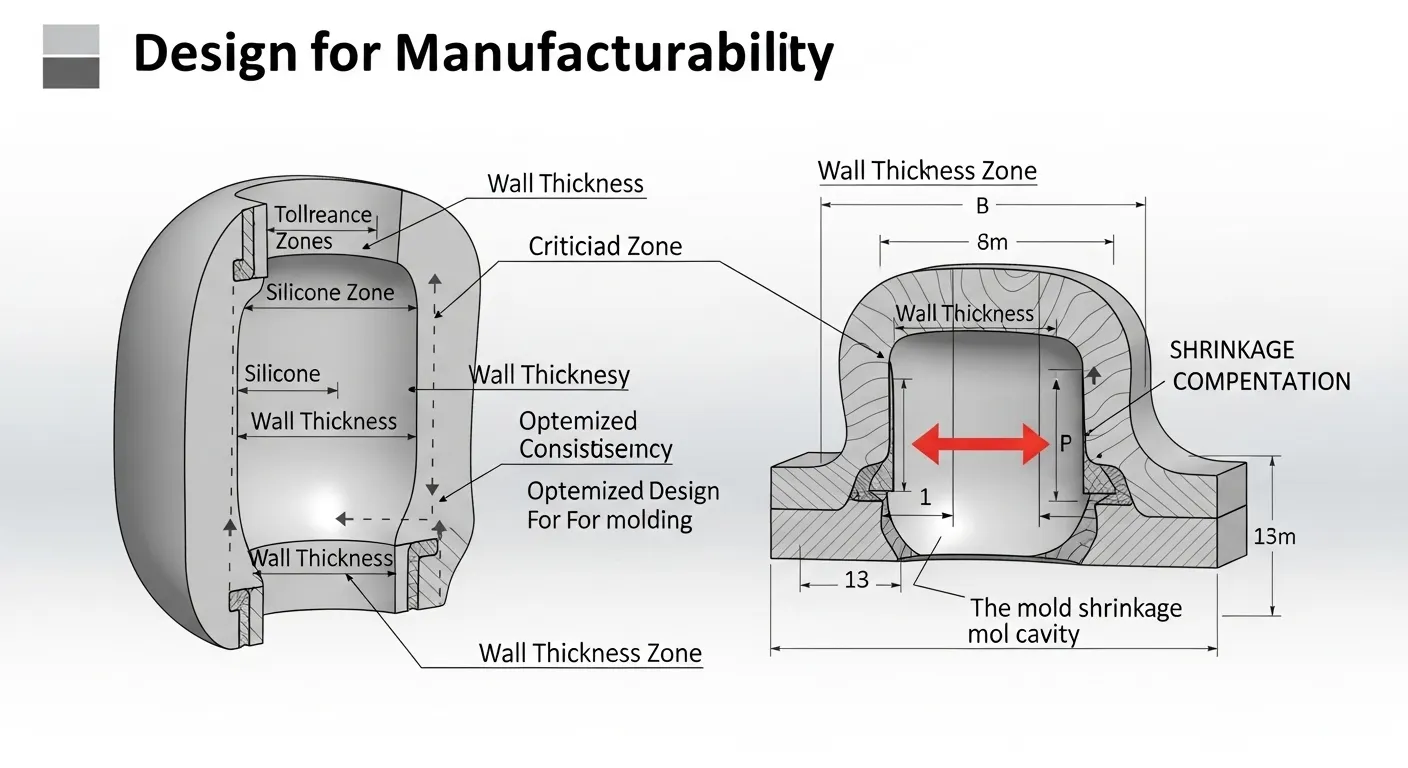

Every silicone grade has a specific linear shrinkage rate. Precision molding requires accounting for this during the tool design phase. If the mold isn't precisely oversized to compensate for how the silicone contracts as it cures, the final part will fail inspection.

How Are Precision Silicone Parts Manufactured?

Achieving micro-level accuracy starts with the custom silicone rubber parts manufacturing process. Unlike standard rubber molding, precision silicone manufacturing relies on high-tech automation and ultra-precise tooling.

- Liquid Silicone Rubber (LSR) Injection Molding: This is the gold standard for high-volume precision. Because LSR is pumped into the mold at a consistent temperature and pressure, it fills complex cavities and thin walls with incredible repeatability.

- Compression Molding: Often used for larger or simpler precision parts, this involves placing a pre-measured amount of high-consistency rubber (HCR) into a heated mold.

- Flashless Tooling: To maintain tight tolerances, molds are designed to produce "flashless" parts, meaning there is no excess material at the parting line that would require secondary trimming.

What is the tightest tolerance for silicone molding?

The tightest standard tolerance for silicone molding is typically around $\pm 0.05mm$ ($0.002$ inches), though this depends heavily on the part's size and geometry. Achieving tolerances tighter than this usually requires specialized "micro-molding" equipment and rigorous environmental controls.

While $\pm 0.05mm$ is possible, it increases production costs significantly. Engineers often use the "standard" tolerance of $\pm 0.1mm$ for non-critical dimensions to keep projects cost-effective. During the design phase, it is helpful to compare these requirements to other precision processes, such as how to choose between zinc and aluminum die casting for your rigid housing components.

Which silicone is best for high-precision parts?

Liquid Silicone Rubber (LSR) is generally considered the best material for high-precision parts due to its low viscosity and excellent flow characteristics. LSR can easily fill intricate mold details that thicker rubbers cannot reach, ensuring that the final part matches the CAD design exactly.

Beyond flow, you must consider the "durometer" (hardness) of the silicone. Softer silicones (20-40 Shore A) are harder to measure accurately because they deform under the pressure of calipers. Harder silicones (60-80 Shore A) tend to hold their shape better, making them easier to verify against tight tolerance specs.

How do you measure precision silicone parts?

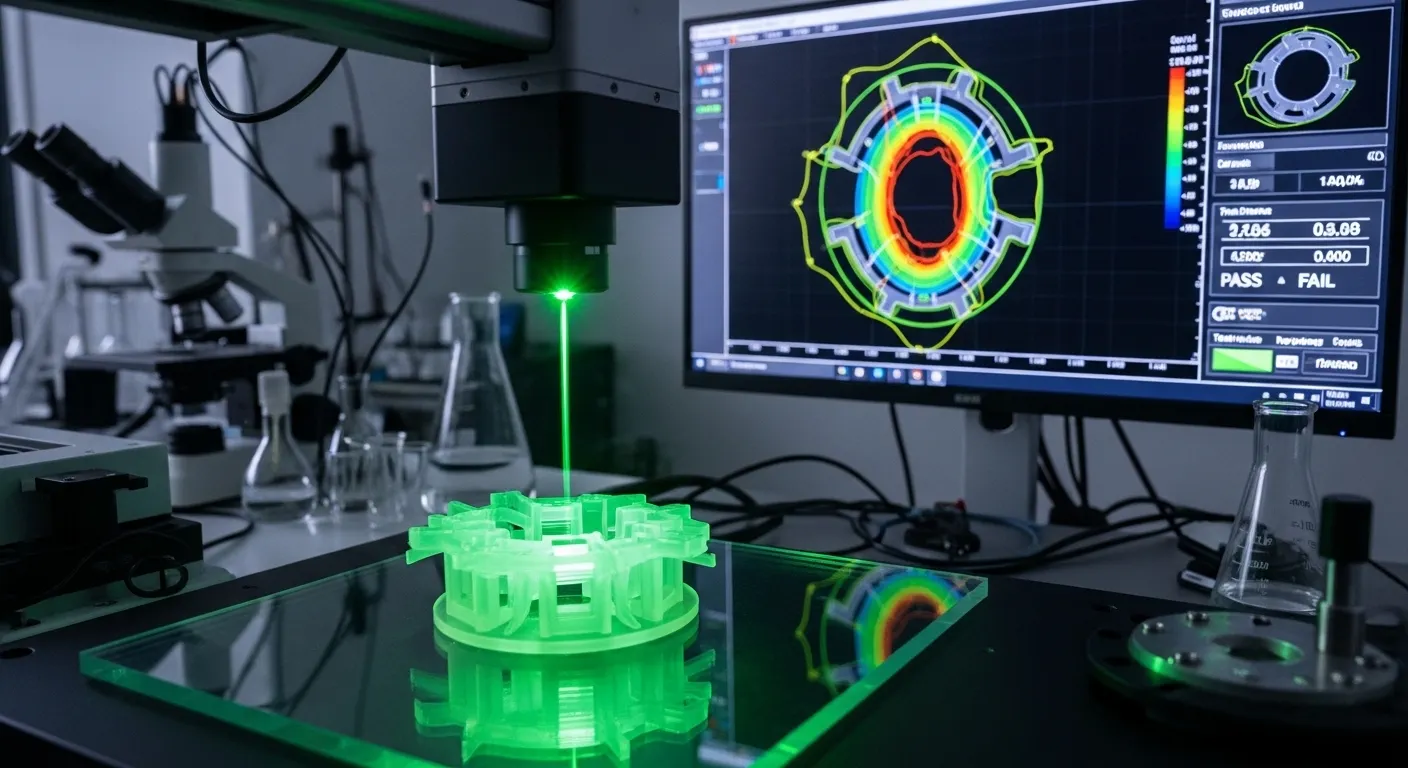

Precision silicone parts are measured using non-contact systems like OGP (Optical Gaging Products) or high-resolution vision systems. Because silicone is flexible, traditional physical calipers can "squish" the part, leading to an inaccurate reading.

Vision systems use cameras and light to map the part's dimensions without touching it. This ensures that the measurements recorded are a true reflection of the part's resting state.

Comparing Silicone Molding to Metal Die Casting for Precision

In many tight tolerance applications, a silicone seal must fit into a metal housing. Understanding the precision capabilities of both materials is vital.

| Feature | LSR Silicone Molding | Zinc Die Casting |

| Typical Tolerance | $\pm 0.1mm$ | $\pm 0.02mm$ |

| Complex Geometries | Excellent (Undercuts possible) | High (Requires draft angles) |

| Material Property | Flexible / Sealant | Rigid / Structural |

| Primary Use | O-rings, Valving, Keypads | Housings, Brackets, Gears |

If your project requires a rigid high-precision housing, you might explore the advantages of zinc die casting for automotive parts or its application in medical device zinc die casting.

Frequently Asked Questions

Yes. Silicone has a high coefficient of thermal expansion. Parts measured in a hot factory may have different dimensions than those measured in a climate-controlled lab.

DFM is the process of optimizing part design—such as adding radiused corners or consistent wall thicknesses—to make it easier to manufacture within the desired tolerances.

Yes, but it is more complex. Overmolding silicone onto a plastic or metal substrate requires precise alignment of the insert within the mold to ensure the silicone layer remains a consistent thickness.

Key Takeaways

- Precision matters: In critical industries, tolerances of $\pm 0.05mm$ ensure safety and functionality.

- LSR is king: Liquid Silicone Rubber provides the best repeatability for complex, tight-tolerance designs.

- Non-contact measurement: Always use optical or vision systems to inspect flexible silicone parts.

- Tooling is the foundation: High-quality, flashless steel molds are required for consistent accuracy.

Conclusion

Precision silicone parts for tight tolerance applications are the unsung heroes of modern technology, ensuring that medical pumps, automotive sensors, and consumer electronics function without fail. By understanding the interplay between material shrinkage, molding technology, and proper inspection, you can ensure your components meet the highest industry standards.

Are you ready to start your next high-precision project? Contact our engineering team today for a DFM analysis and quote on your custom silicone components.