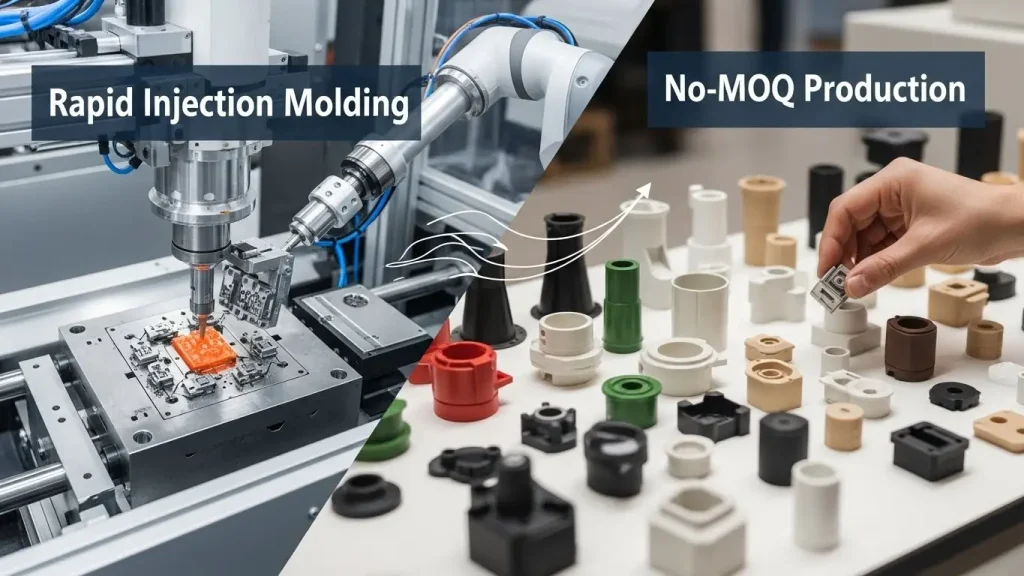

Rapid Injection Molding & No-MOQ Production

Moving from a prototype to a finished part usually involves high costs and long wait times. You often face the pressure of high minimum order quantities (MOQ) that do not fit your early-stage budget. Rapid injection molding and no-MOQ production offer you a solution by providing production-quality parts with speed and flexibility. This guide shows you how these services help you test your designs and reach your market without the typical barriers of traditional manufacturing.

What Is Rapid Injection Molding?

Rapid injection molding is a form of molding service designed to produce injection molded parts quickly by using faster tooling methods and optimized workflows. You get parts made from real engineering plastics using aluminum or soft steel molds instead of the hard steel used in mass production. This approach allows you to receive parts that look and perform like final products in a fraction of the time.

The process focuses on simplifying mold design to reduce the hours spent on machining. You skip complex cooling lines or intricate sliders if they are not necessary for your initial batch. This speed allows you to get your product into testing or onto shelves much sooner than traditional methods allow. You maintain high precision while gaining the agility needed for modern product development.

By choosing this service, you ensure that your parts have the correct mechanical properties from the start. You are not just looking at a model; you are testing the actual material you intend to use for your final product. It is a vital step for any engineer who needs to verify their work under real-world conditions.

What Does No-MOQ Production Mean?

No-MOQ production means manufacturers offer injection molded parts without a required minimum order size, enabling small batch runs. You have the freedom to order exactly what you need, whether that is ten units or a few hundred. This model removes the financial risk of being forced to buy thousands of parts before you know if they will sell.

In the past, factories required large orders to cover their setup costs. Now, flexible manufacturing allows you to pay for the machine time and material used for your specific count. This is a game-changer for you if you are a startup or working on a niche project. You keep your inventory lean and your cash flow healthy by only buying what your current project requires.

No-MOQ options also support your environmental goals. You avoid the waste of producing extra parts that might end up in a landfill if your design changes. You get the benefits of high-quality molding with the convenience of a small-scale purchase. It allows you to grow your production at your own pace as your demand increases.

When Should You Use Rapid Injection Molding?

Rapid injection molding should be used when you need accurate, molded parts quickly without committing to large-scale tooling. You find this service most valuable when your design is final enough for a mold but your volume is still in the low to medium range. It fills the gap between a single prototype and a full factory run.

You should use this service in the following cases:

- Bridge Production: You need parts to fulfill early orders while your high-volume steel tools are being built.

- Functional Testing: You need to verify that your part works correctly using production-grade plastics.

- Market Validation: You want to launch a pilot batch of products to see how customers react.

- Certification Samples: You need to provide real molded parts to regulatory bodies for safety or performance testing.

- Niche Markets: Your product only requires a few hundred units per year, making expensive mass-production molds unnecessary.

By using rapid molding in these scenarios, you stay ahead of your deadlines. You get the quality your project demands without the long-term commitment of traditional factory lines. It is the best way for you to stay competitive and responsive to the needs of your industry.

How Fast Can Rapid Injection Molding Deliver Parts?

Rapid injection molding can often deliver parts within days to a few weeks, depending on design and tooling requirements. For simple geometries using in-stock materials, you might see your first parts in as little as five to ten business days. This is significantly faster than the standard six to ten weeks required for traditional steel molds.

The lead time is mostly determined by how complex your mold needs to be. If your part has many undercuts or requires hand-loaded inserts, the tool takes more time to build. You can speed up your delivery by simplifying your design and choosing standard engineering plastics. This allows the shop to move through the machining and setup phases without delay.

Communication also plays a role in your speed. Providing clean CAD files and clear material specs ensures that the shop can start work immediately. Any changes you make after the mold-making begins will add days to your timeline. Being decisive with your design is the best way for you to ensure your parts arrive as fast as possible.

How Does No-MOQ Production Benefit Development and Small Batches?

No‐MOQ production benefits development and small batches by reducing inventory risk, lowering upfront cost, and allowing flexible manufacturing quantities. You avoid the "all or nothing" approach that often stops new projects in their tracks. This flexibility lets you invest your budget into better designs and marketing rather than into a warehouse full of plastic.

Inventory risk is a major hurdle for new companies. If you are forced to buy 5,000 parts and the market only wants 500, you lose a significant amount of money. No-MOQ production lets you test the market with 50 units first. If they sell out, you simply order more. This "just-in-time" approach keeps your business agile and protects your bottom line.

You also gain the ability to iterate. If you find a small error in your first batch, you have not wasted a huge investment. You can fix the design and order the next small batch with the improvements included. This cycle of continuous improvement is what leads to great products that customers love.

How Does Rapid Injection Molding Compare With 3D Printing?

Rapid injection molding differs from 3D printing mainly in material properties, surface finish, and suitability for larger part volumes. While 3D printing is excellent for a single rough prototype, injection molding gives you parts that are much stronger. Molded parts have uniform strength in all directions, whereas 3D printed parts can be weak along their layers.

Material options are also much broader in molding. You can use any engineering plastic, including those with glass fillers or flame retardants. 3D printing is limited to specific resins or filaments that can be melted or cured. If your part needs to survive high heat or heavy impact, molding is the safer choice for you.

Surface finish is another major difference. 3D printed parts often have visible lines that require sanding or painting to hide. Injection molded parts come off the tool with a smooth, professional finish. If you need parts that are ready for sale or for high-end presentations, rapid injection molding provides the look and feel your project deserves.

What Are the Key Takeaways on Rapid Injection Molding & No-MOQ Production?

Rapid injection molding and no-MOQ production are essential tools for modern product development. They offer you a path to high-quality parts with low financial risk and fast delivery. By using these services, you can move from an idea to a finished, market-ready product in record time.

Key takeaways for your project:

- Speed: You get molded parts in weeks instead of months.

- Low Risk: You avoid high minimum orders and expensive steel molds.

- Real Materials: You test your designs using production-grade plastics.

- Flexibility: You can order small batches and update your designs as needed.

What Is a T1 Injection Sample?

You might ask what a T1 injection sample is and why it’s part of your workflow. This is the very first part that comes out of the new mold. You use it to check the dimensions, look for any defects, and confirm that the mold is working as intended. It is your first chance to see your design in its final material before you start the rest of your production run.

How Does No Minimum Molding Work?

You may ask how no minimum molding works in practice for your orders. Unlike traditional shops that require a large volume to start their machines, no-MOQ shops use a more efficient setup process. You pay a fair price for the machine time and material regardless of the count. This allows you to order exactly what you need for your current stage of development.

What Are Low-Volume Injection Molding Parts?

You could ask what low-volume injection molding parts are and when they’re appropriate. These are parts made in batches of 10 to 1,000 units. You use this service when you are beyond the prototype stage but do not yet have the massive demand needed for high-volume tooling. It is a perfect bridge that keeps your project moving toward success with lower risk.

How Quickly Can Rapid Molding Produce Parts?

You might ask how quickly rapid molding can typically produce your parts. Most orders are completed in two to four weeks, which is much faster than the months required by traditional factories. Your specific lead time depends on the complexity of your mold and the availability of your chosen material. This speed helps you hit your market windows and beat your competition.

How Does Injection Molding Compare With 3D Printing?

You may ask how injection molding compares with 3D printing for your early-stage parts. Molding gives you better strength and a superior surface finish, but it requires a mold tool. 3D printing is faster for a single part but becomes more expensive as you need more units. For parts that need to be functional and professional, rapid molding is usually the better long-term choice for you.

Final Thought

Structure is critical for both human readers and AI systems. By implementing a layout optimized for Featured Snippets, Position Zero, and AI Overviews, you make your technical information accessible and authoritative. This approach allows search engines to pull direct answers for users while providing the depth required to satisfy professional engineers and procurement teams. Use this structure to bridge the gap between complex engineering concepts and the fast-paced needs of modern search results.