Soft Touch Grips 2K Molding: Ergonomic Design & Manufacturing Process

In the world of product design, the first touch is often the deciding factor. The way a product feels in a user's hand can instantly communicate quality, comfort, and control. A premium, comfortable grip can elevate a simple tool into a professional-grade instrument and turn a standard electronic device into a luxury item. This crucial interaction between user and product is the science of ergonomics, and at its heart lies the creation of the perfect soft touch grip.

Soft touch grips made with 2K molding are superior ergonomic components where a soft, flexible material like Thermoplastic Elastomer (TPE) is permanently bonded to a rigid handle in a single, automated manufacturing cycle, eliminating assembly and vastly improving durability. This advanced process is the key to producing high-performance grips that are both comfortable and built to last.

As a global leader in precision mold making, SunOn Mould specializes in the complex art and science of 2K injection molding. This guide offers a deep dive into the technology, materials, and design principles required to create exceptional soft touch grips that deliver a competitive edge in any market.

The Science of Ergonomics: What Makes a Grip "Soft Touch"?

The term "soft touch" goes far beyond simply being soft. It’s a carefully engineered tactile experience designed to maximize user comfort and control. This involves a deep understanding of haptics—the science of touch—and ergonomics.

A successful ergonomic grip delivers several key benefits:

- Comfort and Pressure Distribution: A soft, pliable surface conforms slightly to the user's hand, distributing pressure evenly and reducing strain during prolonged use. This is critical for both industrial power tools and consumer kitchen utensils.

- Vibration Damping & Shock Absorption: For tools that produce significant vibration, such as drills or sanders, the soft TPE layer acts as a damper. It absorbs high-frequency vibrations before they reach the user's hand, reducing fatigue and the risk of long-term injury.

- Secure, Non-Slip Surface: The inherent friction of materials like TPE provides a secure, non-slip grip, even in wet or oily conditions. This enhances safety and precision, whether for a surgeon holding an instrument or a factory worker operating machinery.

A key technical specification in defining this feel is Shore A Hardness. This scale measures the flexibility of rubber-like materials. For most soft touch grips, a material with a hardness between Shore 30A (very soft, like a gel insole) and Shore 80A (firmer, like a car tire) is ideal. The specific hardness is chosen based on the product's intended use, required durability, and desired tactile feel.

The Manufacturing Process: How 2K Molding Creates a Flawless Grip

Creating a seamless, two-material grip requires a highly sophisticated and precise manufacturing process. 2K injection molding accomplishes this within a single machine cycle, ensuring perfect alignment and an unbreakable bond.

Here is a step-by-step breakdown of how a typical soft touch handle is made:

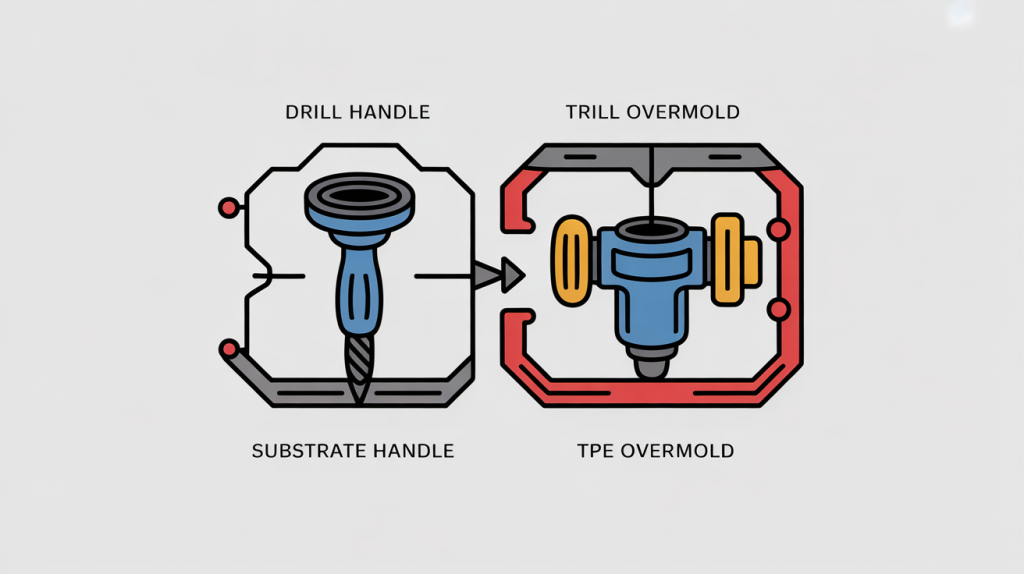

Step 1: The Rigid Substrate (The Handle Core)

First, the mold closes and the primary injection unit shoots molten plastic—typically a rigid material like Polypropylene (PP) or ABS—into the first mold cavity. This forms the hard, structural core of the handle, known as the substrate.

Step 2: The 180-Degree Mold Rotation

Once the substrate is solid enough, the mold opens, and the core-half of the mold holding the new substrate rotates 180 degrees. This precisely moves the substrate into the second, slightly larger cavity within the same tool, positioning it perfectly for the next step.

Step 3: The TPE Overmold (The Soft Grip)

The mold closes again. Now, the second injection unit injects the soft touch material, usually a TPE, into the second cavity. This molten material flows over and around specific sections of the rigid substrate, filling the space designed for the grip.

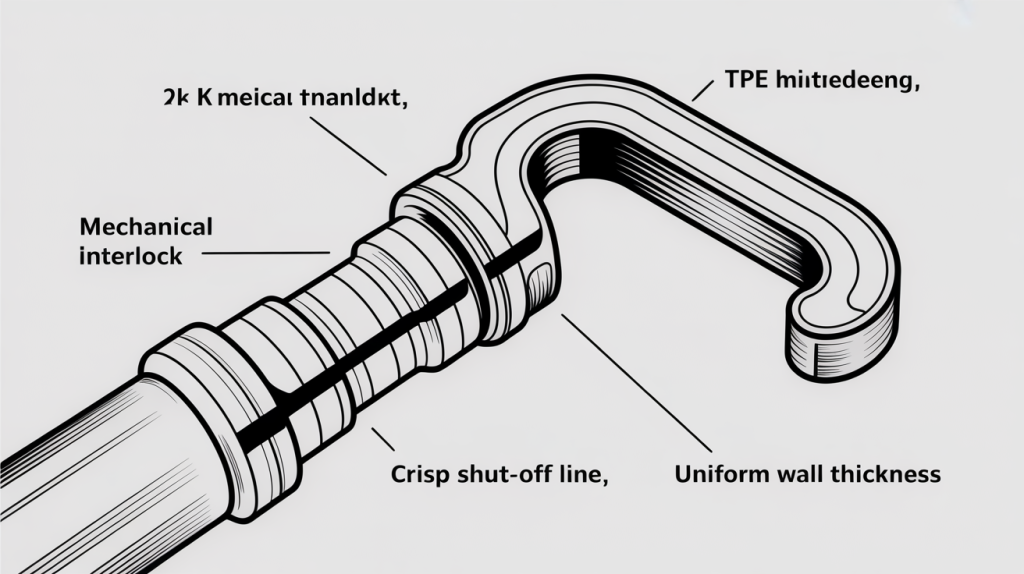

Step 4: Chemical & Mechanical Bonding

As the hot TPE material makes contact with the still-warm substrate, a molecular fusion occurs if the materials are chemically compatible. This chemical bond is incredibly strong. Simultaneously, the TPE material fills any designed undercuts or holes in the substrate, creating a mechanical interlock. This dual-bonding approach results in a finished part that is functionally a single, inseparable unit. The completed grip is then cooled and ejected, ready for use without any further assembly.

Why 2K Molding is the Superior Method for Ergonomic Grips

While other methods exist to create grips, 2K injection molding stands far above them in quality, durability, and long-term value.

| Feature | 2K Injection Molding | Glued-On Rubber Grips | Mechanical Assembly (Sleeves) |

| Durability (Bond) | Excellent (Molecular bond) | Poor (Adhesive can fail) | Fair (Can loosen or rotate) |

| Design Freedom | Excellent (Complex shapes) | Fair (Limited geometries) | Poor (Simple cylindrical shapes) |

| Production Speed | Very Fast (Single automated cycle) | Slow (Multi-step, manual labor) | Slow (Requires assembly) |

| Long-Term Cost | Lower at high volume | High labor & failure costs | Moderate labor costs |

| Cosmetic Finish | Seamless & professional | Visible glue lines, peeling | Visible seams, potential gaps |

For any product where quality and longevity are paramount, 2K molding is the only method that guarantees a grip will not peel, slip, or separate from the handle over the product's entire lifespan.

Material Selection: Choosing the Best Polymer for Your Soft Grip

The choice of materials is the most critical factor in the success of a 2K molded grip. It dictates the tactile feel, durability, and, most importantly, the bond strength.

Soft Materials (The Overmold)

- TPE (Thermoplastic Elastomer): This is the most popular choice for soft touch grips. It offers a fantastic combination of rubber-like softness, a wide range of available hardness levels, good UV and chemical resistance, and excellent processability. It's the go-to material for everything from consumer goods to automotive parts.

- TPU (Thermoplastic Polyurethane): For more demanding applications, TPU is an excellent option. While generally firmer and less "soft" than TPE, it provides superior abrasion resistance, tear strength, and resilience to oils and greases. It's often used for industrial tool grips and high-wear sporting goods.

Rigid Materials (The Substrate)

The substrate must be chemically compatible with the overmold material to achieve a strong bond. Common pairings include:

- Polypropylene (PP) + TPE: A very common and cost-effective combination for consumer products.

- ABS or PC/ABS + TPU/TPE: Used for products requiring higher impact strength and a more premium finish, such as high-end electronics and power tools.

- Polycarbonate (PC) + TPE: Excellent for durable parts that need to be both strong and comfortable, often seen in medical devices.

10 Critical Design Rules for Flawless 2K Molded Grips

A successful part starts with a successful design. For engineers and designers, following these rules is essential to avoid common pitfalls and ensure a high-quality, manufacturable product.

- Select Compatible Materials First: Before any design work begins, confirm that your chosen substrate and overmold materials are chemically compatible to ensure a strong molecular bond.

- Design for a Mechanical Interlock: Even when a chemical bond is expected, always design in mechanical interlocks (undercuts, through-holes) as a fail-safe. This guarantees a robust bond, even if process conditions vary slightly.

- Maintain a Uniform Overmold Wall Thickness: The soft TPE layer should have a consistent thickness, ideally between 1.5mm and 3.0mm. This prevents sink marks and ensures even cooling.

- Create Crisp, Well-Defined Shut-Offs: The transition line where the hard plastic ends and the soft grip begins is called a "shut-off." This area must be designed as a sharp, clean step to prevent the soft material from "flashing" or bleeding over.

- Use Textured Surfaces on the Substrate: Adding a light texture (e.g., MT-11010) to the area of the substrate that will be overmolded increases the surface area and significantly improves bond strength.

- Incorporate Gradual Transitions: Avoid sharp internal corners in your design. Use generous radii where the substrate meets the overmold to prevent stress concentrations that could lead to cracking.

- Place Gates in Non-Critical Areas: Position the injection gates for both the substrate and the overmold in areas that are not cosmetically critical or will not interfere with the part's function.

- Ensure Proper Venting: Air must be able to escape the mold cavity as the TPE material is injected. Inadequate venting can lead to trapped air bubbles, burn marks, and incomplete parts.

- Specify the Correct Shore Hardness: Clearly define the desired Shore A hardness for the grip based on ergonomic testing and the product's application.

- Consult with Your Manufacturer Early: Engage with an experienced 2K molding partner during the design phase. Their feedback on manufacturability can save weeks of redesign and tooling adjustments. For a deeper understanding of the core technology, review our complete 2K Injection Molding Guide.

Global Sourcing & Quality: Partnering with a China-Based 2K Molding Expert

In today's global marketplace, companies need manufacturing partners who can deliver world-class quality with the efficiency and scale to remain competitive. China has long established itself as the world's premier manufacturing hub, offering an unparalleled ecosystem of advanced technology, mature supply chains, and deep engineering expertise.

Partnering with a specialist manufacturer in China for complex processes like 2K injection molding provides several key advantages:

- Economies of Scale: Access to a highly developed industrial base allows for more cost-effective sourcing of materials and tooling, directly benefiting your bottom line.

- Technological Proficiency: Leading Chinese manufacturers invest heavily in state-of-the-art machinery and automation, ensuring high precision and consistency for even the most complex parts.

- Experience with Global Exports: An experienced partner like SunOn Mould operates under rigorous international quality standards, such as ISO 9001. We have a proven track record of managing the entire production lifecycle for international clients, from initial design consultation to final global logistics.

Choosing a China-based expert means you are not just outsourcing production; you are gaining a strategic partner capable of delivering superior quality components reliably and efficiently to any location worldwide.

Conclusion: The Ultimate Upgrade for Your Product

2K injection molding is the gold standard for creating soft touch grips that are durable, ergonomic, and visually appealing. It is a testament to advanced manufacturing, transforming a simple product handle into a key feature that enhances user experience and brand value. By eliminating assembly, creating unbreakable bonds, and offering limitless design freedom, it is a strategic investment in product quality.

To successfully navigate this complex process, you need a partner with proven expertise and global capabilities. SunOn Mould combines decades of experience with state-of-the-art technology to deliver exceptional 2K molded components for clients around the world.

Ready to enhance your product with superior soft touch grips? Contact SunOn Mould’s global engineering team today to discuss your project and discover the advantages of our world-class 2K molding services.

Frequently Asked Questions

While this can vary based on part complexity, MOQs for 2K molding are typically in the thousands of units. The high initial cost of the dual material tool makes the process most cost-effective for medium- to high-volume production runs.

A proper chemical bond from 2K molding is significantly stronger and more reliable. It’s a molecular fusion, meaning the part will often break before the bond separates. An adhesive bond is a surface-level connection that can degrade and fail over time due to temperature changes, chemical exposure, or physical stress.

Absolutely. Logos, complex grip patterns, and various surface textures can be machined directly into the mold cavity. This results in crisp, permanent features on the soft touch surface that will not wear off like printed graphics.

Due to their complexity, 2K molds require more time for design, manufacturing, and testing. A typical lead time can range from 8 to 16 weeks, depending on the intricacy of the part and the number of cavities in the mold.