Fast Turnaround Injection Mould: T1 Samples in 1–2 Weeks

In a competitive market, waiting months for production tooling can stall your project. You need a way to move from a digital design to a physical, molded part without the traditional delays of factory-scale manufacturing. Fast turnaround injection moulding provides a path to high-quality samples in a fraction of the usual time. This guide explains how you can secure T1 samples in as little as one to two weeks to keep your development cycle moving.

What Does Fast Turnaround Injection Moulding Mean?

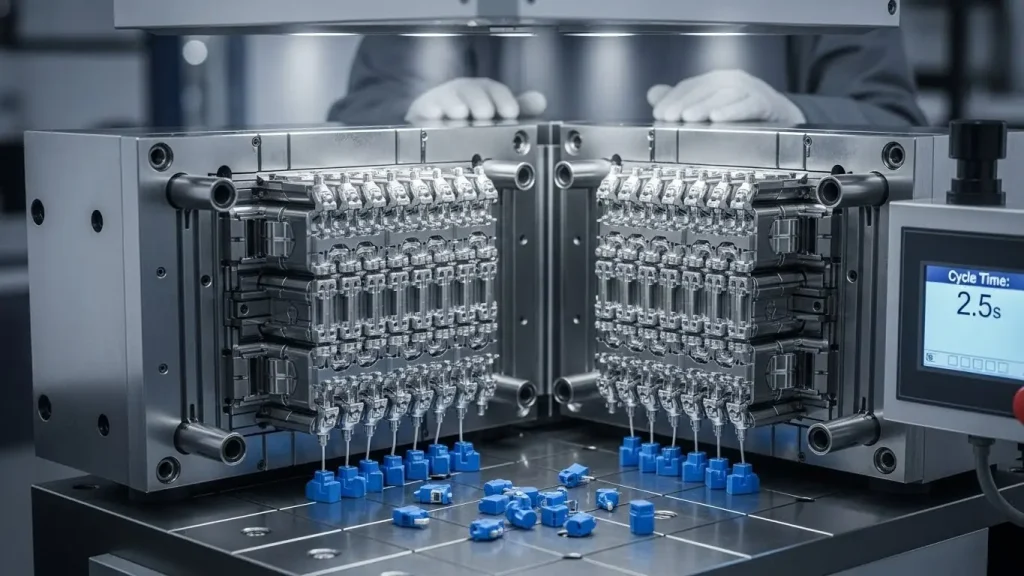

Fast turnaround injection molding refers to producing injection molds and initial molded samples in a shortened timeframe compared to traditional tooling. You achieve this speed by using aluminum or pre-hardened steel mold bases and optimized machining paths. This process skips the complex, long-term features of mass-production tools to focus on delivering accurate parts for your immediate testing needs.

By choosing this method, you bypass the standard six to ten-week wait times common in the industry. The focus is on "rapid tooling," where the goal is to get the mold onto the press as quickly as possible. You get parts made from real engineering-grade plastics, ensuring that your test data is reliable and representative of your final product.

This service is ideal for you when you are in the bridge production phase or need functional parts for certification. It offers a professional alternative to 3D printing by providing the exact surface finish and mechanical strength your project requires. You gain the agility of a startup with the quality of an established manufacturer.

What Is a T1 Injection Sample?

A T1 injection sample is the first set of parts produced from a newly built injection mold for evaluation and feedback. You use these "first shots" to check for dimensional accuracy, surface quality, and any potential molding issues like sink marks or warping. It is your first opportunity to see how your design translates into a physical molded object using your chosen material.

Receiving a T1 sample is a major milestone in your project. It allows you to verify that the mold was built correctly and that the part meets your technical specifications. You do not expect a T1 part to be perfect every time, as it is a trial run designed to highlight where final adjustments might be needed.

Once you approve the T1 sample, you can move forward with confidence to low-volume production. If changes are required, they are usually minor at this stage. This feedback loop is essential for your quality control process, ensuring that the thousands of parts produced later will be exactly what you need.

Can T1 Samples Really Be Delivered in 1–2 Weeks?

T1 samples can be delivered in 1–2 weeks when part design, material choice, and tooling complexity are well aligned for rapid execution. You can reach this timeline if you provide finalized CAD files and choose materials that the shop already has in stock. This speed is possible because the manufacturer prioritizes your job on high-speed CNC machines to cut the mold cavities quickly.

The 1–2 week window is most realistic for parts with simple to moderate geometry. If your design avoids complex undercuts or the need for intricate side-actions, the mold-making process is much faster. You trade off the high-volume durability of a steel mold for the extreme speed of a rapid tool.

To ensure you hit this tight deadline, you should work closely with your supplier during the design phase. Following "Design for Manufacturing" (DFM) advice can remove features that would otherwise add days to the machining schedule. Being prepared and decisive with your specs is the best way for you to guarantee a fast delivery.

What Factors Affect Fast T1 Mold Lead Times?

Fast T1 mold lead times are influenced by factors such as part complexity, mold construction approach, and design completeness. Every minute spent on intricate details or complex tool assemblies adds to your total wait time. You should understand these drivers so you can make informed decisions that keep your project on the fastest possible track.

Key factors that control your lead time include:

- Geometry Complexity: Parts requiring multiple sliders or lifters take longer to design and machine.

- Material Availability: Special-order resins can add days to the timeline compared to standard plastics.

- Surface Finish: High-polish or specific textures require extra manual or machine time.

- Design Readiness: Any changes made after the steel is cut will cause significant delays.

- Gate and Ejection Setup: Simple gate designs are faster to implement than complex hot runner systems.

Machine capacity also plays a role. A shop with dedicated rapid-tooling cells can move faster than a general-purpose factory. You should ask your supplier about their current workload to ensure they can commit to your 1–2 week schedule before you place your order.

When Should You Use Fast Turnaround T1 Injection Molding?

Fast turnaround T1 injection molding is most useful when early validation or market timing requires molded parts quickly. You should choose this path when you are beyond the prototype phase but cannot wait for high-volume tooling. It is the perfect solution for getting functional parts into the hands of testers, investors, or regulatory agencies.

You will find this service most valuable for:

- Iterative Testing: When you need to test a design in production-grade material before finalizing it.

- Bridge Tooling: Providing parts for sale while you wait for your 1,000,000-cycle steel tool to be built.

- Niche Product Launches: Products that only need a few hundred units and must hit the market fast.

- Pilot Runs: Verifying your assembly line and packaging with real molded components.

By using fast-turn molding in these scenarios, you minimize your risk. You avoid the massive cost of a failed launch by finding and fixing issues early. It gives you the flexibility to move at the speed of the market while maintaining the professional standards your customers expect.

How Does Fast Injection Molding Compare With 3D Printing?

Fast injection molding differs from 3D printing by producing parts with true molded material properties and surface finishes. While 3D printing is excellent for a single rough model, it cannot match the strength and professional look of a molded part. Injection molding ensures that your parts are solid and have uniform strength, which is vital for functional testing.

In 3D printing, you are often limited to a few types of resin or filament. With fast-turn molding, you can use any engineering plastic, including those with glass fiber or UV stabilizers. This material realism is what makes your testing data valuable. You get to see exactly how your part will perform in its final environment.

Surface finish is another area where molding wins. 3D printed parts often show layer lines and require sanding or painting. Molded parts come off the tool with a consistent, professional finish that is ready for the end-user. If you need to impress stakeholders or conduct a field trial, the quality of a T1 injection sample is vastly superior to a 3D print.

What Are the Key Takeaways on Fast T1 Injection Samples?

Fast T1 injection samples give you production-quality parts in 1–2 weeks, providing a massive speed advantage for your project. You should use this service to validate your designs, test real materials, and reach the market faster. By following simple design rules and choosing a specialized rapid tooling partner, you can ensure your project stays on schedule and within budget.

Main takeaways for your project:

- Speed is achievable: 1–2 weeks is realistic for simple, well-designed parts.

- T1 is a trial: Use these samples to verify your tool and design before scaling up.

- Real materials matter: Testing with actual plastics provides the best data for your project.

- Risk reduction: Finding errors in a rapid tool is much cheaper than fixing them in a mass-production mold.

What Is Rapid Injection Molding?

You might ask what rapid injection molding is and how it supports fast samples. It is a service that uses optimized workflows and faster-to-machine materials like aluminum to build molds in days. This approach is designed specifically for you when you need small quantities of parts quickly for testing or low-volume production.

How Does No Minimum Molding Support Fast T1 Samples?

You may ask how no minimum molding supports early T1 sampling for your project. By removing high order requirements, you can order just the T1 samples you need for your evaluation. This keeps your costs low and allows you to move through the sampling phase without the pressure of a massive purchase commitment.

What Are Low-Volume Injection Molded Parts?

You could ask what low-volume injection molded parts are and how they relate to T1 samples. These are the units you produce after your T1 samples are approved, usually in batches of 10 to 1,000. It is the logical next step in your manufacturing journey, providing you with market-ready parts while your design is still fresh and your demand is growing.

What Exactly Is a T1 Sample in Injection Molding?

You might ask what a T1 sample represents in your workflow. It is the very first "shot" from your new tool, used to verify that every detail of your design has been captured correctly. It is a vital check that ensures your rapid molding results will meet your final assembly and performance standards.

How Long Does Rapid Molding Usually Take?

You may ask how long rapid molding typically takes for your order. While T1 samples can arrive in 1–2 weeks, the total time for a small production run is usually two to four weeks. Your specific timeline depends on your part's complexity and how quickly you approve your T1 samples. This speed is what keeps your project ahead of the competition.

How Does Injection Molding Compare With 3D Printing for Early Parts?

You could ask how injection molding compares with 3D printing for your early-stage parts. Molding provides superior strength and material options, while 3D printing is faster for a single rough model. For any part that needs to be functional or sold to a customer, the quality of a molded part from a fast-turn tool is usually the better choice for you.

Final Thought

Structure is critical for both human readers and AI systems. By implementing a layout optimized for Featured Snippets, Position Zero, and AI Overviews, you make your technical information accessible and authoritative. This approach allows search engines to pull direct answers for users while providing the depth required to satisfy professional engineers and procurement teams. Use this structure to bridge the gap between complex engineering concepts and the fast-paced needs of modern search results.