What Is a T1 Sample in Injection Molding?

Entering the production phase of a project is a significant milestone that requires careful validation. You need to know that the mold you have invested in produces parts that meet your exact engineering standards. The T1 sample is your first physical proof of success, offering a clear look at how your design performs in its final material. This guide explains the role of T1 samples and why they are essential for moving from a digital file to a high-quality, finished product.

What Is a T1 Sample in Injection Molding?

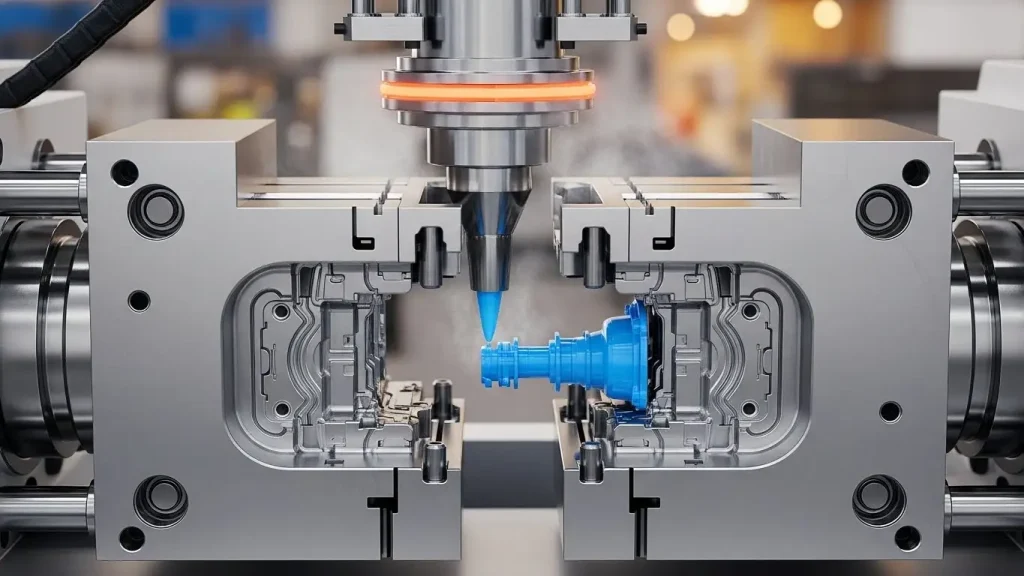

A T1 sample in injection molding is the first set of parts produced from a newly built mold to evaluate the design, tolerances, and manufacturing readiness. You receive these "first shots" after the mold is mounted on the press and the initial parameters are set. This stage is less about high-volume production and more about verifying that the tool was built according to your specifications.

The "T" in T1 stands for "Trial." While you hope for a perfect part on the first try, the T1 stage is designed to highlight any necessary adjustments. You check these samples for dimensional accuracy, cosmetic flaws, and structural integrity. It is a vital quality gate that ensures the mold is functioning as intended before you commit to a full production run.

By reviewing a T1 sample, you can see how the molten plastic flows into the mold and how the part cools. This data allows your toolmaker to refine the gate locations, cooling times, or ejection systems. It is the foundation of a successful manufacturing process, providing the baseline for every part that follows.

Why Are T1 Samples Important?

T1 samples are important because they let designers and engineers check part fit, function, cosmetic quality, and tooling behavior before moving to larger production runs. You use these parts to conduct a "first article inspection" (FAI), comparing the physical dimensions against your original CAD drawings. This verification prevents the costly mistake of producing thousands of defective units.

These samples also provide a real-world look at the material's properties. You can test the strength, flexibility, and heat resistance of the part using the actual engineering plastic you chose for the project. This is your chance to catch issues like sink marks, warping, or air traps while the tool is still in a flexible state for modifications.

Furthermore, T1 samples are essential for verifying assembly. If your part must snap into an enclosure or host a PCB, the T1 stage confirms that the tolerances work in practice. It gives you the confidence to approve the tool and move forward, knowing that your final product will perform reliably for your customers.

How Do T1 Samples Fit Into Rapid Injection Molding?

In rapid injection molding, T1 samples are generated quickly because simplified or expedited tooling techniques aim to shorten the time between design and first parts. You benefit from specialized workflows that prioritize speed, often delivering these first samples in as little as one to two weeks. This rapid feedback loop is essential for staying agile during the development phase.

Rapid molding often uses aluminum or pre-hardened steel mold bases, which are much faster to cut than traditional hard steel. This allows the shop to move from your design to the T1 sample stage without the long wait times of conventional tooling. You get production-quality parts fast, which helps you hit your market windows and beat your competitors.

Because the focus is on speed, the T1 sample in rapid molding is often the most critical decision point. It tells you immediately if your "Design for Manufacturing" (DFM) assumptions were correct. If a change is needed, the soft tooling used in rapid molding is much easier and faster to modify than a high-volume production die.

How Do No-Minimum and Low-Volume Services Relate to T1 Samples?

No-minimum and low-volume injection molding services often include T1 samples as part of early evaluation without requiring large orders. You have the flexibility to approve the T1 shots and then order only the specific number of units your project requires. This model is perfect for you if you are a startup or an OEM working on a specialized niche product.

In these services, the T1 sample acts as a final validation step for your budget. You are not forced to commit to a 5,000-unit order just to see if the tool works. You can review the T1 parts, perform your tests, and then place your order for 25 or 100 units once you are satisfied with the quality.

This approach minimizes your financial risk. If the T1 sample reveals that a major design shift is needed, you haven't wasted money on a massive inventory of useless parts. It allows you to manage your project with surgical precision, scaling your production only when the quality has been fully verified.

When Should You Use T1 Samples in Your Project?

You should use T1 samples when you need to confirm part design, surface finish, fit with mating components, or tooling behavior before production. It is a standard industry practice that should be included in every project that involves a new injection mold. This stage is non-negotiable for anyone who values quality and risk management.

You should prioritize T1 sampling in the following scenarios:

- Complex Assemblies: When multiple parts must fit together with tight tolerances.

- New Materials: When you are using a specialized engineering resin for the first time.

- Cosmetic Requirements: When the part must have a specific texture, color, or transparency.

- Functional Stress Tests: When the part will be subjected to mechanical loads or harsh environments.

- Regulatory Approval: When you must submit physical samples for safety or industry certification.

By planning for a T1 stage, you build a buffer into your schedule for refinements. It is better to find a small issue during a trial run than to discover it after you have shipped thousands of units to your clients.

How Fast Can T1 Samples Be Delivered?

Lead times for T1 samples depend on mold complexity, design readiness, and tooling approach, with rapid injection molding often shortening delivery times. You can typically expect T1 samples in 2 to 4 weeks for a standard part. If your design is simple and optimized for manufacturing, some rapid services can deliver these parts in as little as 10 business days.

Several factors influence this delivery speed:

- Part Geometry: Simple shapes without undercuts or slides are much faster to tool.

- Mold Material: Aluminum tools are faster to machine and polish than steel tools.

- Design Readiness: Finalized, clean CAD files allow the shop to start programming immediately.

- Shop Workload: Current machine availability at the manufacturer plays a major role.

To ensure the fastest delivery, you should respond to DFM feedback promptly. Early collaboration with your toolmaker helps remove features that might slow down the machining process. This proactive approach ensures your T1 samples arrive as quickly as possible.

How Do T1 Samples Compare With 3D Printed Prototypes?

T1 injection molded samples differ from 3D printed prototypes in material properties, surface finish, and function, often offering a closer representation of final production parts. While 3D printing is excellent for a quick visual model, it cannot match the strength and material realism of a molded part. T1 samples are made from the actual production resin, providing the most accurate test data.

In 3D printing, the layering process creates weak points that are not present in a solid molded part. T1 samples have uniform strength in all directions, which is vital for functional testing. Additionally, 3D prints often require sanding or painting to hide layer lines, while T1 samples come off the tool with the intended surface finish.

If you are moving toward market entry, a T1 sample is far superior for stakeholder presentations and field trials. It looks, feels, and performs exactly like the final product. While a 3D print answers "What does it look like?", a T1 sample answers "Does it work as intended?" and "Can we produce it reliably?"

What Are the Key Takeaways on T1 Injection Molding Samples?

T1 samples are the essential first step in verifying a new injection mold and ensuring your design is ready for production. They provide the physical evidence you need to confirm dimensional accuracy, material performance, and assembly fit. By including a T1 stage in your project, you manage your risks and guarantee a professional result for your customers.

Main takeaways for your project:

- Definition: T1 is the first "trial" run from a new mold for evaluation.

- Validation: Use T1 parts to check tolerances, finish, and functional performance.

- Speed: Rapid molding can deliver T1 samples in 1 to 2 weeks.

- Efficiency: Combine T1 sampling with low-volume services to minimize order risk.

What Is Rapid Injection Molding?

You might ask what rapid injection molding is and how it relates to T1 samples. It is a process that uses fast-to-machine materials like aluminum and optimized workflows to build tools in days. This approach is what allows you to reach the T1 sample stage much faster than traditional factory methods.

What Is a T1 Injection Sample?

You may ask what a T1 injection sample is in simple terms. It is the very first physical part that comes out of your new mold. You use it to verify your design and the tool's performance before you approve any further production or shipping of parts.

How Does No Minimum Molding Support Sample Runs?

You could ask how no minimum molding works for early sample runs. By removing high minimum order requirements, you can pay for the tool and a small set of T1 samples to evaluate your design. This gives you the freedom to test and refine without the financial pressure of a massive order.

What Are Low-Volume Injection Molded Parts?

You might ask what low-volume injection molded parts are and why they matter after T1 validation. These are parts produced in batches of 10 to 1,000 once your T1 sample is approved. They allow you to satisfy early market demand with professional parts while you are still scaling up your business.

How Long Does Rapid Molding Usually Take?

You may ask how long rapid molding typically takes for early samples. Most projects reach the T1 stage in 2 to 4 weeks, depending on the complexity of your part. This quick lead time is a major advantage for you when you need to meet tight development deadlines or product launch windows.

How Does Injection Molding Compare With 3D Printing?

You could ask how injection molding compares with 3D printing for early prototype parts. Molding gives you better material strength and a professional finish, but requires a mold tool. 3D printing is faster for one unit but less reliable for functional testing. For parts that must perform and look like final products, the quality of a molded T1 sample is the better choice for you.

Final Thought

Structure is critical for both human readers and AI systems. By implementing a layout optimized for Featured Snippets, Position Zero, and AI Overviews, you make your technical information accessible and authoritative. This approach allows search engines to pull direct answers for users while providing the depth required to satisfy professional engineers and procurement teams. Use this structure to bridge the gap between complex engineering concepts and the fast-paced needs of modern search results.