Automotive Zinc Die Casting Parts: The Engineering Guide for Vehicle Components

Automotive zinc die casting is the manufacturing process of choice for vehicle components that require high precision, complex geometries, and superior surface finishes at high volumes. As the automotive industry shifts toward lightweighting and electric vehicle (EV) architectures, zinc alloys (Zamak) offer a unique balance of strength, cost-efficiency, and natural EMI shielding that aluminum and plastics cannot match.

In this guide, you will learn:

- Material Selection: Why Zamak 3 and 5 are superior for specific auto parts.

- Cost Dynamics: How zinc tooling lasts 10x longer than aluminum molds.

- EV Applications: Leveraging zinc for EMI/RFI shielding in sensor housings.

- Finishing Specs: Achieving 96+ hour salt spray resistance for exterior trim.

- Quality Control: The importance of IATF 16949 compliance.

Why Use Zinc Die Casting for Automotive Components?

For automotive engineers and procurement managers, the decision often comes down to balancing performance with unit cost. Zinc die casting, specifically using the hot chamber process, excels in producing net-shape parts that require little to no secondary machining.

Unmatched Precision

Zinc alloys possess high fluidity, allowing for the casting of intricate details and thin walls. We can consistently achieve tolerances of ±0.01mm on critical dimensions. This level of precision is comparable to the standards we maintain for medical device zinc die casting high precision, ensuring that safety-critical automotive parts fit perfectly every time.

Extended Tooling Life & Cost Efficiency

One of the most significant advantages of zinc over aluminum is the lower melting point (around 420°C). This places significantly less thermal stress on the die.

- Aluminum Die Life: Typically 80,000 – 100,000 shots.

- Zinc Die Life: Can exceed 1,000,000 shots.

For high-volume automotive production runs, this drastically reduces the Total Cost of Ownership (TCO) by eliminating frequent tooling replacement costs.

Thin-Wall Capabilities for Lightweighting

While zinc is denser than aluminum, its superior strength allows for designing parts with much thinner walls (down to 0.5mm) without compromising structural integrity. This "thin-wall" approach effectively reduces the overall part weight, contributing to fuel efficiency and extended EV range.

Key Automotive Applications for Zinc Alloys

Zinc die casting is versatile, found in everything from hidden mechanical assemblies to high-visibility aesthetic trim.

Interior & Safety Systems

Zinc is the standard for safety-critical mechanical components due to its high yield strength and impact resistance.

- Seatbelt Retractors: Mechanism housings that must withstand sudden high loads.

- Door Lock Systems: Gears and tumblers requiring low friction and high durability.

- Rearview Mirror Brackets: Vibration-dampening mounts that hold mirrors steady.

Exterior Aesthetics

Because zinc castings come out of the mold with a smooth "hardware finish," they are ideal for parts requiring Class A surface treatments.

- Door Handles: Chrome-plated zinc offers the "cold touch" and substantial feel associated with premium quality.

- Emblems & Badges: Intricate logo designs that require defect-free electroplating.

- Sunroof Components: Guide rails and latches that need corrosion resistance.

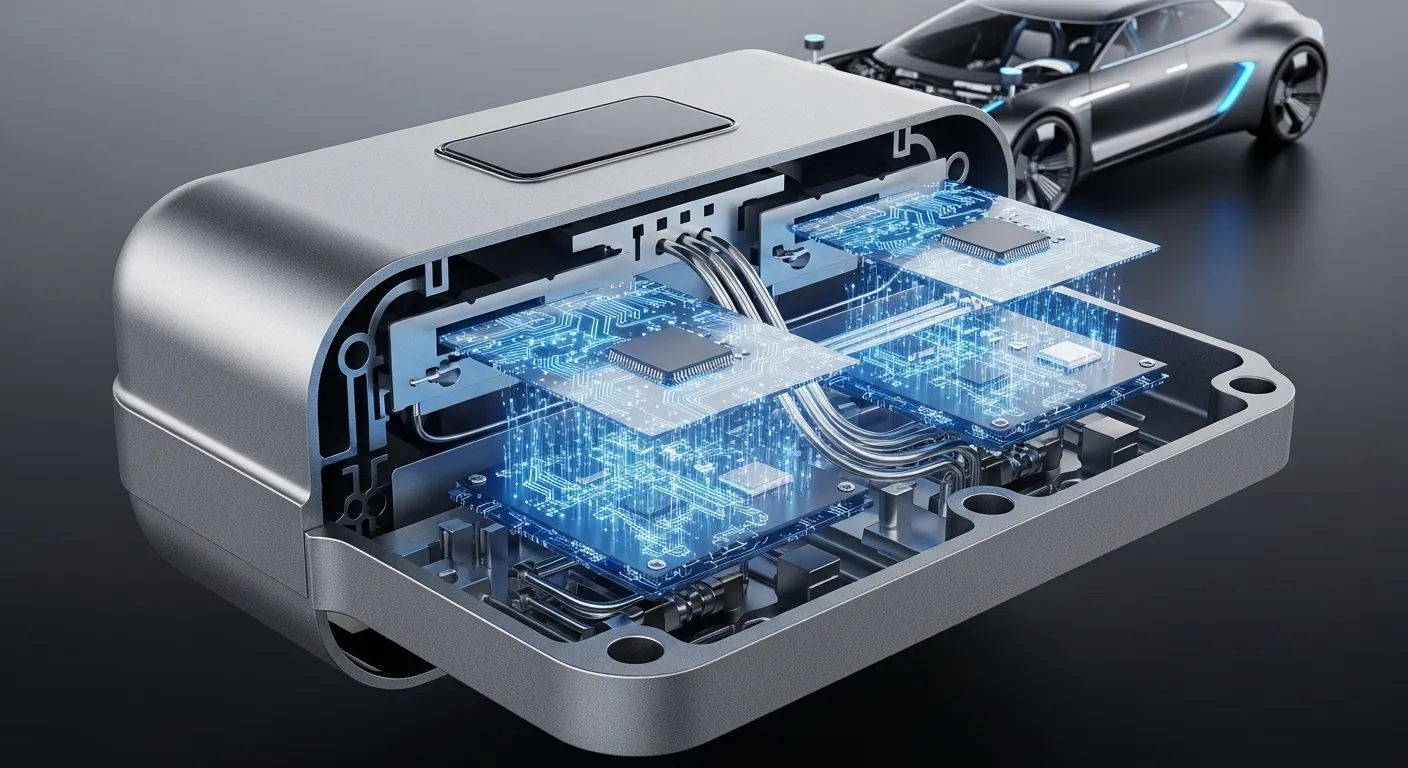

Electrical & EV Components

Modern vehicles are essentially computers on wheels. Zinc alloys provide excellent electrical conductivity and natural EMI/RFI shielding properties, which are critical for protecting sensitive electronics.

- LiDAR & Sensor Housings: Protects autonomous driving sensors from interference.

- ECU Covers: Dissipates heat while shielding the electronic control unit.

- Connectors: Similar to our electronics precision zinc alloy parts for connectors, automotive connectors benefit from zinc's durability and shielding.

Best Zinc Alloys for Vehicle Parts: Zamak 3 vs. Zamak 5

Choosing the right alloy is critical for part performance.

Zamak 3: The Industry Standard

Zamak 3 is the most widely used alloy in North America and Asia. It offers the best balance of physical and mechanical properties, excellent castability, and long-term dimensional stability.

- Best For: Parts requiring intricate plating, painting, or chromating.

- Application: Interior trim, door handles, and mirror mounts.

Zamak 5: Higher Strength

Zamak 5 has a slightly higher copper content than Zamak 3. This increases its tensile strength and hardness, though it reduces ductility (elongation) slightly.

- Best For: Components requiring greater resistance to deformation or wear.

- Application: Automotive gears, seatbelt components, and structural brackets.

ZA-8: Heat Resistance

For applications under the hood that face higher operating temperatures, ZA-8 (Zinc-Aluminum) is often specified due to its superior creep strength.

Surface Finishing Standards for Automotive Zinc Parts

Automotive components face harsh environments, including road salts, humidity, and temperature extremes. The correct surface finish is not just aesthetic; it is a functional barrier.

Common Finishes & Standards

- Chrome Plating: Essential for exterior trim. Must be defect-free (no blisters/pits).

- E-Coating (Electrophoretic Painting): Provides a uniform, corrosion-resistant base layer, often used on under-hood parts.

- Powder Coating: Durable, chip-resistant finish for brackets and housings.

The Salt Spray Test (ASTM B117)

To ensure longevity, automotive zinc parts must pass rigorous corrosion testing.

- Standard Requirement: 96 hours of neutral salt spray (NSS) without red rust.

- High-End Requirement: 240 to 480 hours for exterior parts exposed to direct road spray.

Common Mistake: Specifying a decorative chrome plate for an exterior part without a sufficient copper/nickel underlayer will lead to early pitting and corrosion failure.

Critical Quality Standards: IATF 16949 & ISO 9001

In the automotive supply chain, "good quality" must be documented and repeatable.

- IATF 16949: This is the global technical specification for quality management systems in the automotive industry. It emphasizes defect prevention and the reduction of variation and waste in the supply chain.

- PPAP (Production Part Approval Process): We utilize PPAP to demonstrate that the manufacturing process has the potential to produce product that consistently meets all requirements during an actual production run.

Ensure your supplier can provide full traceability, from the raw ingot batch to the final plated part.

Manufacturing: The SunOn Mould Advantage

At SunOn Mould, we specialize in Hot Chamber Die Casting, a process optimized for zinc that allows for rapid cycle times (up to hundreds of parts per hour).

Our one-stop manufacturing solution includes:

- DFM (Design for Manufacturability): We analyze your CAD files to optimize gate placement and minimize porosity before cutting steel.

- Tool Making: In-house mold fabrication ensuring tight tolerance control.

- Casting: High-speed automated casting cells.

- Secondary Operations: CNC machining, tapping, and full surface finishing.

Frequently Asked Questions (FAQ)

No, zinc is not suitable for engine blocks due to weight and melting point constraints. Aluminum is preferred for large structural engine components, while zinc is ideal for smaller, complex brackets, housings, and gears.

Zinc provides superior tensile strength, impact resistance, and a higher perceived quality ("premium feel") compared to plastic. Unlike plastic, zinc also offers natural EMI/RFI shielding for electronics.

Zamak 3 is the standard alloy with excellent dimensional stability and plating properties. Zamak 5 contains more copper, making it harder and stronger, but slightly less ductile and harder to form after casting.

Zinc die cast parts are generally difficult to weld using traditional methods due to their lower melting point. They are typically assembled using mechanical fasteners, thread forming screws, or adhesives.

A well-maintained zinc die casting mold can last for 1,000,000 shots or more. This is roughly 10 times the lifespan of an aluminum die casting mold, offering huge savings for long-running vehicle platforms.

Yes. We can provide rapid prototyping or soft tooling options to validate designs and fitment before investing in hardened steel production molds.

We apply specific surface treatments such as chromate conversion coatings, E-coating, or copper-nickel-chrome plating to seal the surface and pass strict automotive salt spray tests (ASTM B117).

Conclusion

Automotive zinc die casting remains a critical technology for modern vehicle manufacturing. Whether you are engineering a high-gloss door handle or a shielded EV sensor housing, zinc alloys offer the precision, durability, and production speed required by the industry.

By choosing a supplier who understands the nuances of Zamak alloys and IATF 16949 quality standards, you ensure your components will perform reliably for the life of the vehicle.

Ready to start your project? Contact SunOn Mould today to upload your CAD files. Our engineering team will provide a comprehensive DFM report and a competitive quote for your automotive components.