High Temperature Resistant Silicone Parts for Industrial Use: A 2026 Engineering Guide

High temperature resistant silicone parts are essential components designed to maintain structural integrity and elasticity in environments reaching up to 300°C. In industrial manufacturing, these parts provide critical sealing, insulation, and vibration dampening where standard elastomers would melt or become brittle.

By the end of this guide, you will be able to:

- Identify the specific temperature limits of various silicone grades.

- Compare silicone against alternative high-heat elastomers like EPDM and Viton.

- Optimize part design for custom low volume silicone rubber production for prototypes.

- Select the appropriate molding process for complex industrial geometries.

Why Silicone is the Standard for Extreme Heat Environments

Silicone rubber is unique due to its chemical backbone. Unlike organic rubbers with a carbon-to-carbon backbone, silicone features a siloxane (silicon-oxygen) structure. This bond is significantly stronger and more resistant to thermal energy, allowing the material to operate continuously at temperatures where other materials oxidize and fail.

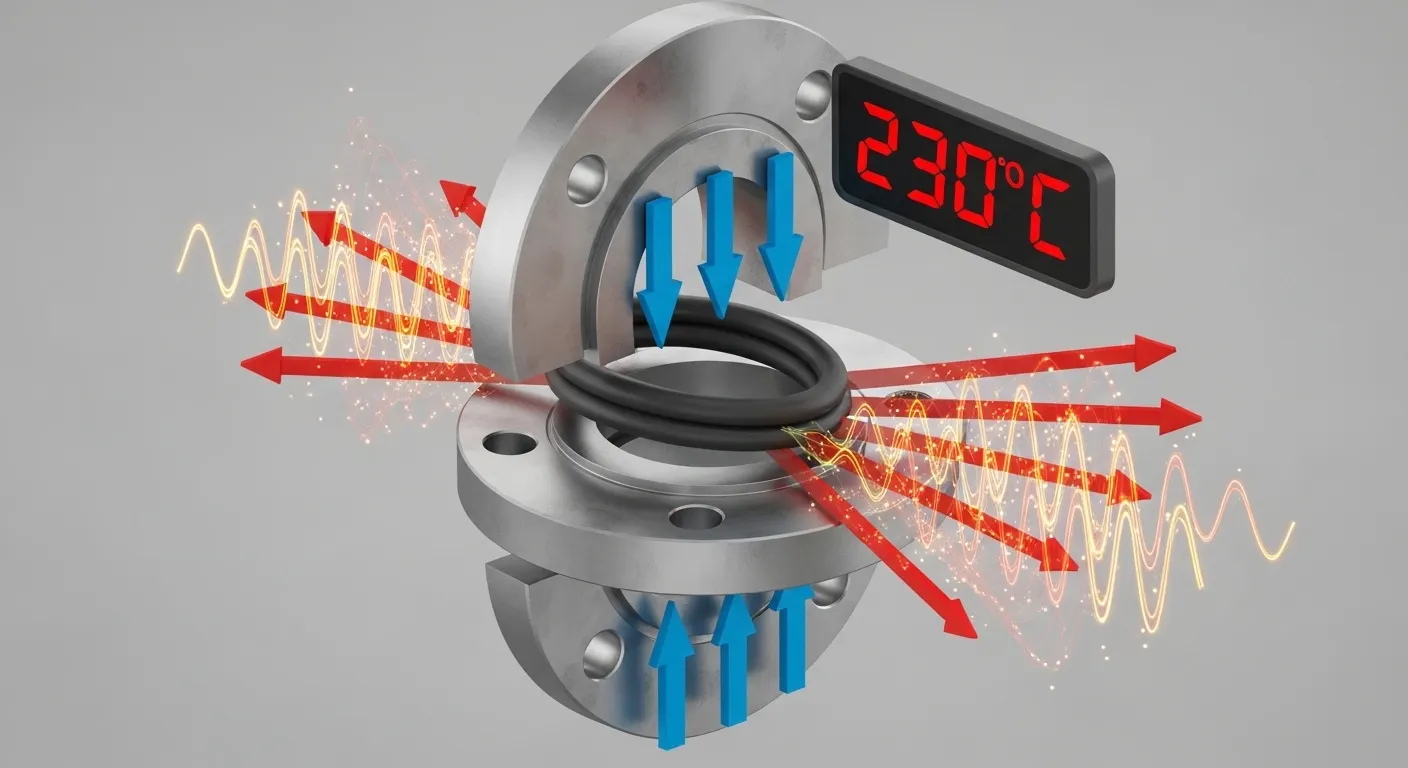

Standard industrial silicone typically operates within a range of -60°C to +230°C. However, the engineering of high-consistency rubber (HTV) or liquid silicone rubber (LSR) with thermal stabilizers can push these limits. In 2026, the demand for these parts is surging, particularly in thermal management for electric vehicle (EV) batteries and high-performance computing.

Common Mistake: Many procurement teams assume all silicone is "high temp" by default. Standard-grade silicone may fail prematurely if exposed to continuous temperatures above 200°C without specific heat-stabilizing additives like cerium oxide.

Key Properties of Industrial Heat-Resistant Silicone

Thermal Aging & Compression Set

In industrial sealing, "compression set" refers to a material's inability to return to its original thickness after being compressed under heat. High-temperature silicone is engineered for a low compression set, ensuring that aerospace silicone seals and gaskets high performance maintain a leak-proof barrier even after years of thermal cycling.

Chemical & UV Resistance

Beyond heat, industrial environments often involve exposure to UV radiation and ozone. Silicone remains chemically inert in these conditions. However, it is important to note that while silicone handles heat well, it can swell when in contact with certain concentrated fuels or oils unless a fluorosilicone grade is used.

Material Comparison: Silicone vs. EPDM & Viton (FKM)

- EPDM: Cost-effective but limited to roughly 150°C. It fails rapidly in the high-heat zones of modern engines.

- Viton (FKM): Excellent chemical resistance and handles up to 250°C, but it is significantly more expensive and loses flexibility at low temperatures compared to silicone.

- Silicone: The "middle ground" that offers the widest temperature range and superior flexibility for general industrial use.

| Material | Temp Range (Continuous) | Chemical Resistance | Best Use Case |

| EPDM | -50°C to 150°C | Good | Outdoor Seals |

| Viton | -20°C to 250°C | Excellent | Fuel Systems |

| Silicone | -60°C to 230°C+ | Moderate | Industrial Heat |

Top Industrial Applications for High-Temp Silicone Parts

The versatility of silicone makes it indispensable across several high-stakes sectors:

- Automotive: Turbocharger hoses, spark plug boots, and engine gaskets that must endure constant heat soak.

- Aerospace: Firestop seals and ducting where safety-critical thermal insulation is required.

- Medical & Food Tech: Medical silicone rubber components FDA compliant are required for instruments that undergo repeated steam sterilization (autoclaving) at high temperatures.

- New Energy: Thermal interface pads for EV batteries that manage heat during rapid charging cycles.

Manufacturing Custom Heat-Resistant Parts: LSR vs. Compression Molding

Choosing the right manufacturing process impacts both the part's performance and your project's total cost.

- Liquid Silicone Rubber (LSR) Molding: Best for high-precision, high-volume production. It is ideal for intricate silicone rubber molding for complex geometries where tight tolerances are mandatory.

- Compression Molding: Typically used for larger, simpler parts or lower volume runs. It is highly cost-effective for thick-walled gaskets and seals.

Pro Tip: For 2026 projects, consider the "T1" sample phase carefully. Ensure your manufacturer uses the exact production-grade high-temp resin during prototyping to accurately simulate thermal expansion.

Design for Reliability: Avoiding Common Failure Points

To ensure your high-temp parts don't fail in the field, avoid these common design pitfalls:

- Improper Durometer Selection: Using a silicone that is too hard (high durometer) can lead to cracking under thermal expansion.

- Underestimating Chemical Swell: If your high-temp environment also includes oil mist, standard silicone may swell by up to (needs verification)% and lose its seal.

- Sharp Internal Corners: High heat stresses the material; always use radii to distribute stress and prevent tearing during thermal cycling.

Frequently Asked Questions

Can silicone withstand 300°C?

Yes, but only specialized "High Heat" grades with stabilizers can withstand 300°C, and usually only for intermittent periods rather than continuous use.

How long does silicone last at high heat?

At 200°C, a high-quality industrial silicone part can last for several years. At its maximum limit of 250°C–300°C, the service life may drop to weeks or hundreds of hours depending on the grade.

Does high temperature change the color of silicone?

Standard silicone may yellow or darken over time when exposed to extreme heat. If color stability is required (e.g., in lighting applications), specific UV and heat-stable pigments must be used.

Is silicone better than EPDM for heat?

Yes, silicone significantly outperforms EPDM in heat resistance. While EPDM maxes out around 150°C, silicone maintains its mechanical properties up to 230°C and beyond.

What is the "compression set" of high-temp silicone?

Industrial high-temp silicones typically offer a compression set as low as 10–20% (needs verification) when tested at 175°C for 22 hours, ensuring long-term sealing reliability.

Can I use high-temp silicone in vacuum environments?

Yes, silicone has low outgassing properties, making it suitable for high-heat vacuum applications in laboratory and semiconductor equipment.

Conclusion

Selecting high temperature resistant silicone parts for industrial use requires a balance of material science and precise manufacturing. By understanding the limits of different silicone grades and choosing the right molding process, you can ensure long-term reliability in the most demanding environments.

Ready to start your next project? Contact SunOn-Mould today for an expert consultation on custom silicone molding and high-temperature material selection.

Would you like me to generate the SEO metadata (slug and meta description) for this post now?