Low Volume Silicone Rubber Production for Prototypes: The 2026 Guide

The best way to bridge the gap between a digital concept and a market-ready product is through low volume silicone rubber production. This strategy allows you to validate functional designs using production-grade materials without the prohibitive costs of high-volume steel tooling.

With this guide, you will control:

- Method Selection: Match your part count (1 to 1,000+) to the most cost-effective process.

- Material Accuracy: Ensure your prototype's durometer and heat resistance match final production.

- Lead Times: Reduce development cycles from months to as little as 3–7 days.

- Budget Efficiency: Minimize NRE (Non-Recurring Engineering) costs by utilizing rapid tooling.

Choosing the Right Prototyping Method (Selection Matrix)

In 2026, the "best" method is defined by your specific volume and functional requirements. For basic fit-tests, 3D printing suffices, but for aerospace silicone seals and gaskets high performance, you need a process that handles high-tear strength materials.

| Feature | 3D Printed Molds | RTV Casting | Rapid LSR Injection |

| Ideal Volume | 1–10 parts | 10–50 parts | 50–1,000+ parts |

| Lead Time | 1–3 Days | 3–7 Days | 10–15 Days |

| Tolerance | ±0.15mm | ±0.10mm | ±0.05mm |

| Tooling Cost | $100 - $300 | $200 - $800 | $2,000 - $5,000 |

Common Mistakes to Avoid: > Ignoring Material Properties: Using 3D printed "silicone-like" resins for functional testing; these rarely match the compression set or thermal stability of real Liquid Silicone Rubber (LSR).

Over-Volume RTV: Pushing RTV (Room Temperature Vulcanization) molds beyond 50 shots. The soft mold degrades, leading to dimensional drift and surface finish issues.

Core Technologies for Low Volume Silicone Production

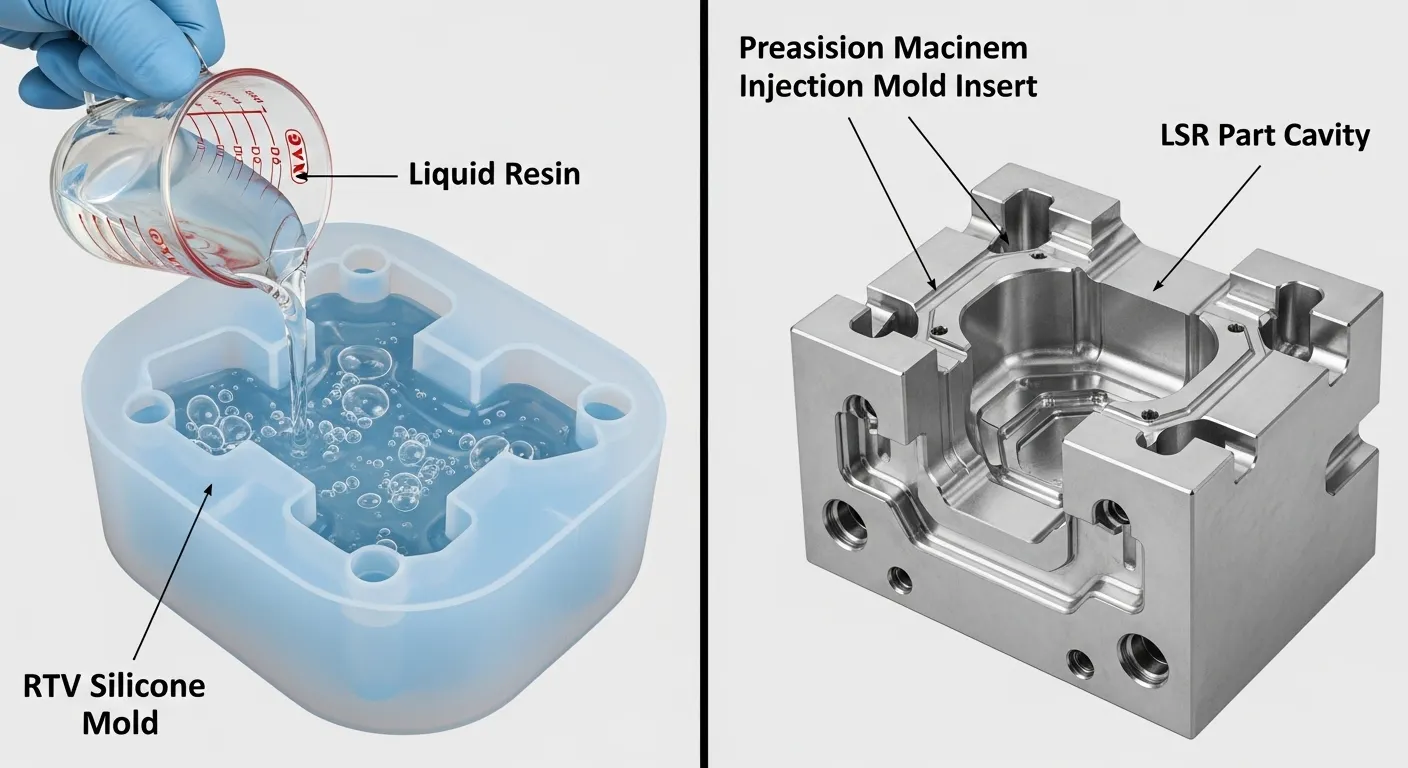

RTV (Room Temperature Vulcanization) Casting

RTV casting uses a "soft" silicone mold to cast parts. It is the gold standard for low-volume runs where aesthetics and basic functionality are priorities. Because the mold is flexible, it can often accommodate slight undercuts without complex lifters, making it ideal for intricate silicone rubber molding for complex geometries.

Quick-Turn Liquid Silicone Rubber (LSR) Injection Molding

For prototypes that require medical-grade certification or high-speed validation, rapid LSR molding is preferred. We use aluminum or soft steel molds that interface with professional injection molding machines. This ensures the part produced is 100% identical to what will eventually come off a mass-production steel tool.

Compression Molding for Simple Geometries

If your part is a simple slab, O-ring, or gasket, compression molding is the most economical path. It involves placing a pre-measured "slug" of high-consistency rubber (HCR) into a heated cavity. While cycle times are slower than injection, the tooling is significantly cheaper.

Designing for Manufacturability (DFM) in Silicone Prototypes

Silicone behaves differently than thermoplastics. While it is incredibly forgiving regarding undercuts (you can often "peel" a part off a core), it is highly sensitive to wall thickness and air entrapment.

Key Design Checklist:

- Wall Thickness: Aim for a range of 0.5mm to 5.0mm. Excessive thickness leads to "sink" and uneven curing.

- Draft Angles: While silicone can be demolded with zero draft, adding 0.5° to 1° significantly extends the life of your prototype mold.

- Gate Placement: For medical silicone rubber components fda compliant, gates should be placed in non-critical areas to prevent "flash" or burrs that could compromise hygiene or seal integrity.

Common Mistake: > Sharp Internal Corners: These create stress concentrations that cause prototypes to tear during demolding. Always use a minimum radius of 0.5mm.

Cost Factors & Lead Times in 2026

The cost of low-volume production is heavily weighted toward the initial tooling. In 2026, savvy engineers use Master Unit Die (MUD) inserts to save up to 50%–70% on tooling costs. By using a universal frame that stays in the machine, you only pay for the custom-machined "insert" that forms your part.

Typical Cost Breakdown (needs verification):

- RTV Tooling: $400 - $900 (includes master pattern and silicone mold).

- Aluminum Injection Tooling: $2,500 - $4,500 (best for 100+ units).

- Piece Price: For low volumes, expect $5.00 to $25.00 per part, depending on material grade (e.g., standard vs. high-transparency optical silicone).

Industry Applications

Low-volume production is the lifeblood of specialized hardware. In the tech sector, we produce electronics silicone parts for insulation and protection that must pass rigorous UL-94 flame retardancy tests before mass assembly begins.

Industry Examples:

- Medical: Rapid prototyping of surgical handles or respiratory masks for clinical trials.

- Automotive: Small batches of connector seals for EV battery cooling systems.

- Consumer Tech: Wearable straps and protective cases for field testing.

When selecting a partner for low-volume production, ensure they provide the following "Trust Signals":

- Material Data Sheets (TDS): Never accept "generic silicone." Demand specific brand data (e.g., Wacker or Dow Corning).

- Dimensional Inspection Reports: Even for prototypes, a sample of 3–5 parts should be measured against your CAD to verify tolerances.

- ISO Compliance: Ensure the facility operates under ISO 9001:2015 standards for quality management.

Frequently Asked Questions

What is the best way to prototype silicone parts?

The best method depends on volume: 3D printing for 1-5 units (fit-check only), RTV casting for 10-50 units (functional testing), and rapid injection molding for 100+ units (production-grade validation).

How much does a silicone prototype mold cost?

A simple RTV mold usually costs between $200 and $800, while a rapid aluminum injection mold typically ranges from $2,000 to $5,000 depending on complexity.

Can you 3D print production-grade silicone?

Direct 3D printing of pure silicone is possible but rare and expensive; most "silicone-like" 3D resins lack the mechanical durability and heat resistance of real molded LSR.

What is the typical lead time for silicone prototypes?

RTV cast parts are usually delivered in 3 to 7 business days, whereas rapid injection molded parts require 10 to 15 days due to the metal machining required for the mold.

How many parts can I get from one RTV mold?

You can typically get 20 to 50 shots from a single RTV silicone mold before the dimensions begin to warp or the surface finish degrades.

What is the difference between RTV and LSR?

RTV (Room Temperature Vulcanization) cures at ambient temperatures and is used for manual casting, while LSR (Liquid Silicone Rubber) is a platinum-cured material processed via high-speed injection molding for higher precision.

Conclusion

Low volume silicone rubber production is no longer a "one-size-fits-all" process. By choosing between RTV casting and rapid injection molding based on your specific testing phase, you can drastically reduce your time-to-market while ensuring your parts meet industry standards for aerospace, medical, or electronics.

Ready to validate your design?

Contact Sunon-Mould today for a technical DFM review and a rapid quote on your low-volume silicone project.

Would you like me to help you generate any specific meta-data or social media snippets for this post?