Medical Device Zinc Die Casting: Engineering High Precision

High-precision zinc die casting provides medical device OEMs with the ability to manufacture complex, net-shape components with tolerances as tight as ±0.0015 inches. This process is essential for creating durable, RFI-shielded housings and intricate internal components that meet the rigorous safety standards of the healthcare industry.

By reading this guide, you will:

- Evaluate zinc's technical advantages over aluminum and plastic.

- Determine the best Zamak alloy for your specific medical application.

- Identify methods to eliminate secondary machining costs.

- Control quality outcomes through ISO-compliant manufacturing standards.

Why High-Precision Zinc Casting for Medical Devices?

In the medical sector, the "feel" and reliability of a device often correlate with its perceived quality. Zinc alloys are significantly denser than aluminum or plastic, providing a "substantial" weight to handheld surgical tools and diagnostic equipment. Beyond aesthetics, zinc’s high fluidity allows for the casting of ultra-thin walls (as low as 0.3mm to 0.5mm), which is critical for miniaturizing modern medical tech.

Because zinc has a lower melting point than aluminum, it causes less thermal shock to the molds. This results in an exceptionally long tool life—often exceeding one million shots—ensuring consistent precision across high-volume production runs.

Technical Specs: Tolerances and Net-Shape Advantages

The primary driver for choosing zinc in medical engineering is the achievement of "net-shape" components. This means the part comes out of the die requiring little to no secondary machining, saving significant labor and time.

- Dimensional Accuracy: Standard precision typically reaches ±0.0015 inches per inch.

- Surface Finish: Zinc produces a smooth, "as-cast" surface that easily accepts medical-grade antimicrobial coatings or chrome plating.

- Draft Angles: Zinc requires smaller draft angles than other metals, allowing for more vertical walls in complex housings.

Common Mistakes to Avoid: > * Over-specifying tolerances: Requesting ±0.0005" when ±0.002" is sufficient unnecessarily increases tooling complexity and cost.

- Ignoring Draft: Even with zinc’s fluidity, failing to include minimum draft angles can lead to part distortion during ejection.

Critical Applications in Modern Healthcare

Zinc is versatile enough to serve in both structural and aesthetic capacities across the hospital environment.

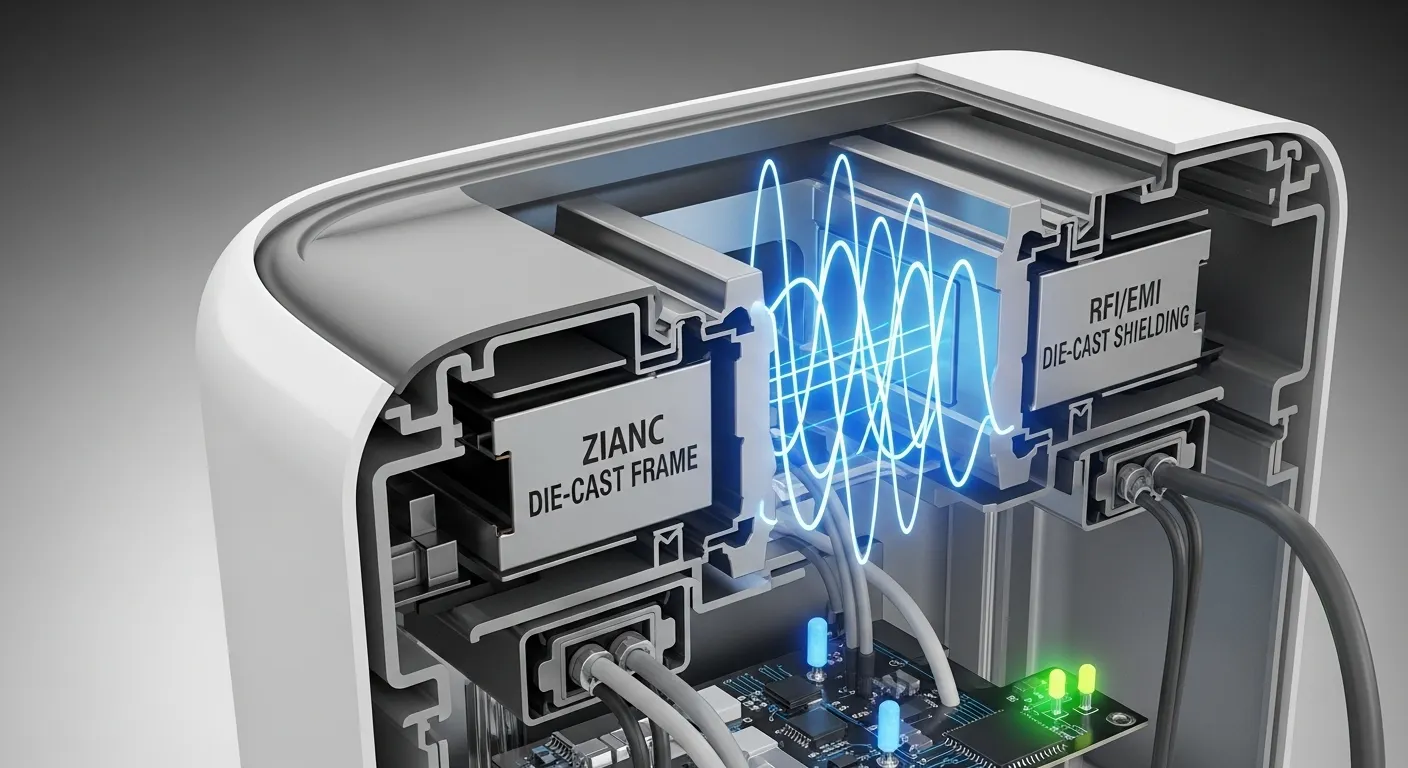

Diagnostic & Imaging Equipment (RFI/EMI Shielding)

Medical electronics are highly sensitive to interference. Zinc is an inherent shield against Radio Frequency Interference (RFI) and Electromagnetic Interference (EMI). Unlike plastic, which requires expensive conductive coatings, zinc components provide built-in protection for sensitive circuitry in MRI machines and bedside monitors. This level of protection is similar to that required for electronics precision zinc alloy parts for connectors, where signal integrity is paramount.

Surgical Instruments & Miniature Components

For robotic surgery and handheld devices, zinc provides the high strength-to-weight ratio needed for gears, levers, and triggers. Its vibration-damping properties also make it ideal for power-assisted surgical tools, reducing hand fatigue for surgeons.

Hospital Infrastructure

From bed locking mechanisms to monitor mounts, zinc components provide the structural integrity required for heavy-use environments. The durability required for these components is often compared to automotive zinc die casting parts for vehicle components, as both industries demand zero-failure reliability under stress.

Material Selection: Which Medical Grade Zinc Alloy?

Choosing the right alloy is a balance of mechanical requirements and environmental exposure.

- Zamak 3: The industry standard for medical casting. It offers the best balance of physical and mechanical properties, excellent finishability, and the highest ductility.

- Zamak 5: Includes a higher copper content, providing increased strength and hardness. Use this for load-bearing components like monitor arm joints.

- ZA-8: Known for its creep resistance, ZA-8 is ideal for components that will be under constant load or exposed to elevated temperatures during sterilization cycles.

Compliance & Reliability

Manufacturing for the medical industry is a high-stakes endeavor. Adhering to ISO 9001:2015 standards ensures every batch meets the strict traceability requirements of the medical field.

While zinc is generally considered safe, it is vital to consider surface treatments. Many medical devices undergo harsh sterilization (autoclaves or chemical wipes). Zinc parts are typically powder-coated, E-coated, or plated to provide a non-porous, chemically resistant barrier that stands up to hospital-grade disinfectants.

FAQ: High-Precision Medical Zinc Casting

Zinc itself is not typically used for long-term implants, but it is excellent for external medical devices. When properly plated or coated, it meets the requirements for non-direct-contact surgical tools and diagnostic equipment.

Zinc allows for tighter tolerances and thinner walls than aluminum due to its lower casting temperature and higher fluidity. It can often eliminate the CNC machining steps that aluminum requires.

Yes, especially when using alloys like ZA-8. However, a proper surface finish (such as specialized plating) is recommended to prevent oxidation during repeated high-pressure steam cycles.

Tooling for high-precision medical molds typically takes 4 to 6 weeks, depending on the complexity of the part geometry and the required tolerance levels.

Yes, zinc alloys are naturally conductive and provide excellent EMI/RFI shielding without the need for the conductive paints or vacuum metallization required for plastic parts.

While zinc is often used for small, intricate parts, high-pressure die casting machines can produce components ranging from a few grams up to several kilograms.

Conclusion

High-precision zinc die casting remains a cornerstone of medical device manufacturing because it bridges the gap between complex design and structural reliability. By leveraging zinc’s superior fluidity and shielding properties, OEMs can produce sophisticated, net-shape components that perform under pressure.

Ready to optimize your next medical project? Contact Sunon-Mould today to discuss your technical specifications or request a high-precision manufacturing quote.