Advantages of Zinc Die Casting for Automotive Parts: A 2026 Engineering Guide

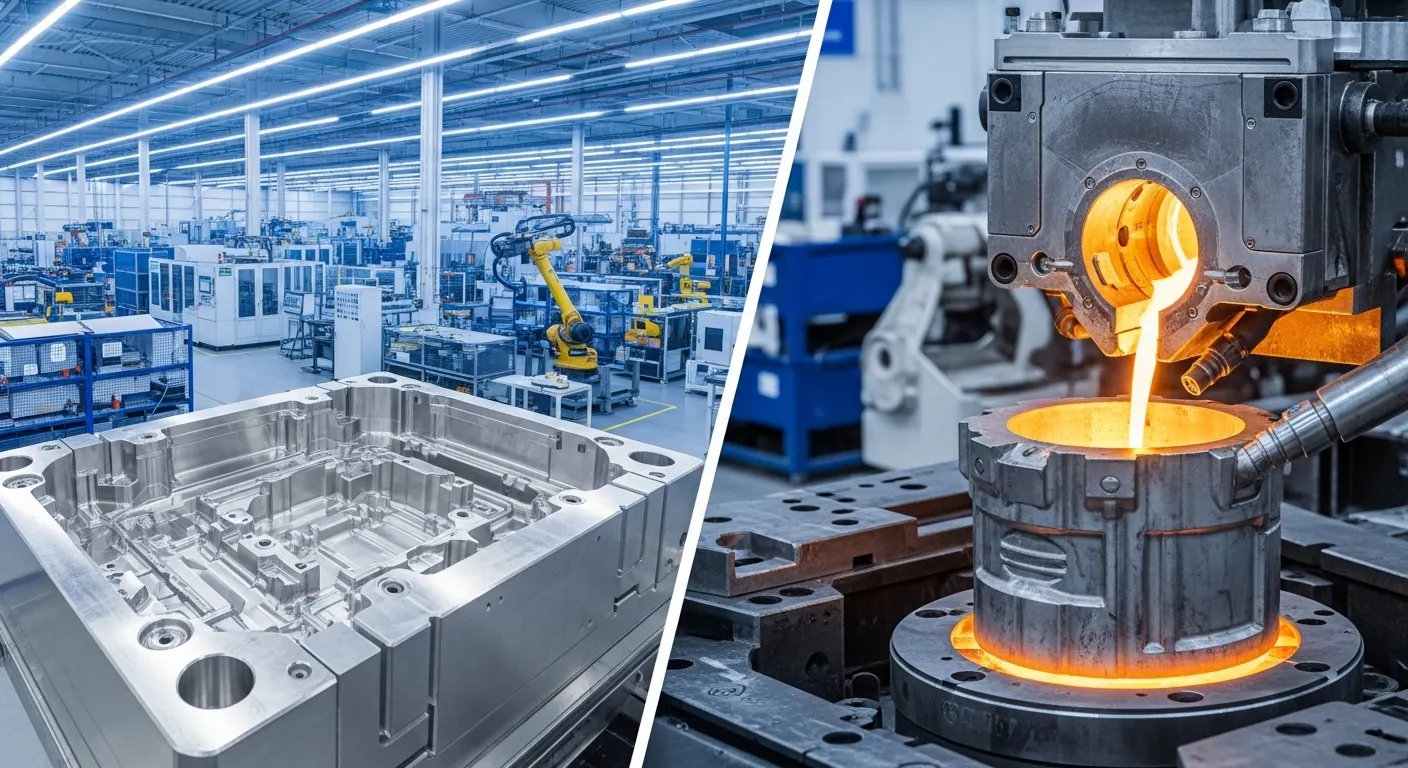

Zinc die casting allows automotive manufacturers to achieve net-shape excellence by producing components with ultra-tight tolerances of ±0.02mm. At SunOn, our hot-chamber process enables the creation of complex geometries and thin-wall sections down to 0.25mm, virtually eliminating the need for costly secondary machining while ensuring perfect dimensional accuracy.

In our 20+ years of manufacturing experience, we have found that the fluidity of zinc alloys is the "secret weapon" for modern automotive interiors and functional parts. While other materials struggle with intricate details, our work with zinc consistently delivers parts that require zero post-mold trimming to fit into high-precision assemblies.

Tight-Tolerance Automotive Components

- Sensor Housings: Protective enclosures for ADAS and autonomous driving sensors.

- Fuel System Connectors: High-sealing components requiring perfect interface fit.

- Interior Trim Brackets: Complex clips and supports for dashboards and steering columns.

- Door Lock Mechanisms: Multi-part assemblies where ±0.02mm precision is non-negotiable.

The Economic Edge: Cycle Speed and Tooling Longevity

Zinc die casting offers a superior economic edge because its low melting point significantly extends tooling longevity, often exceeding 1 million shots. Unlike aluminum, zinc utilizes the hot-chamber process, which reduces cycle times by up to 50%, allowing SunOn to deliver high-volume orders with lower amortized costs and higher efficiency.

Our facility in Dongguan specializes in high-volume production where tool life is the primary driver of ROI. We utilize H13-type hot die steel treated to HRC50, ensuring that our molds—like those used for Mercedes-Benz and BMW components—maintain their integrity over hundreds of thousands of cycles without the heat-checking issues common in aluminum casting.

Manufacturing Efficiency Comparison: Zinc vs. Aluminum

| Performance Metric | Zinc Alloy (Zamak 3) | Aluminum Alloy (A380) |

| Melting Temperature | ~380°C - 390°C | ~580°C - 600°C |

| Cycle Speed | High (Hot-Chamber) | Moderate (Cold-Chamber) |

| Typical Tool Life | 500,000 - 1,000,000+ Shots | 80,000 - 150,000 Shots |

| Thin Wall Minimum | 0.25 mm | 0.5 mm |

| Secondary Machining | Minimal to None | Often Required |

Material Performance in Harsh Environments

Zinc alloys provide exceptional performance in harsh automotive environments due to their high impact strength, ductility, and natural corrosion resistance. These properties make zinc an ideal choice for safety-critical components like seat belt retractors and airbag housings, where the material must absorb energy and maintain structural integrity under extreme stress.

We have integrated material composition testing into our quality assurance system to ensure every batch of automotive zinc die casting parts meets IATF 16949 standards. In our testing, Zamak alloys demonstrate superior "wear and tear" resistance compared to plastic or even some aluminum grades, specifically in mechanical assemblies that see constant use.

Key Mechanical Advantages

- High Ductility: Allows for post-casting operations like crimping or riveting without fracturing.

- Self-Lubrication: Excellent for moving parts in door handles and sunroof tracks.

- Vibration Damping: Superior to aluminum, reducing noise, vibration, and harshness (NVH) in the cabin.

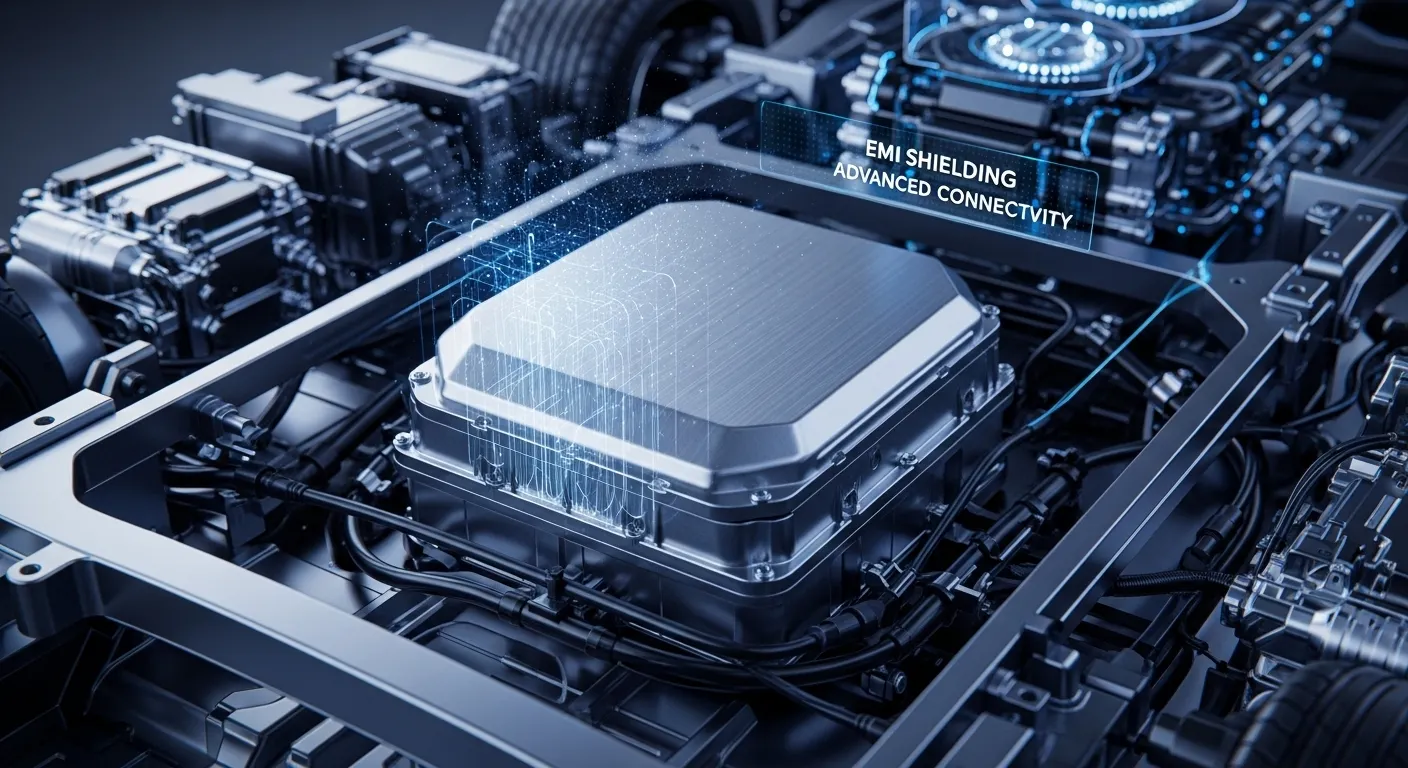

The EV Revolution: Shielding and Lightweighting

Electric Vehicle (EV) production relies on zinc die casting for its inherent EMI and RFI shielding capabilities, which protect sensitive electronic control units. By utilizing zinc's ability to cast ultra-thin walls, SunOn helps engineers reduce component weight without sacrificing the electromagnetic protection required for 2026’s advanced ADAS and connectivity modules.

As the automotive industry shifts toward total electrification, our engineers have seen an increased demand for electronics precision zinc alloy parts used in connectors and inverter housings. Zinc blocks interference far more effectively than plastic or aluminum, ensuring that high-voltage cables don't disrupt low-voltage signals in the vehicle's brain.

Sustainability: The 100% Circular Supply Chain

Zinc die casting is a cornerstone of the circular supply chain because the material is 100% recyclable without losing its mechanical properties. SunOn supports global sustainability goals by utilizing a process that requires significantly less energy than aluminum smelting and produces minimal waste, aligning with ISO 14001:2015 environmental standards.

At our 32,000 square meter plant, we operate a closed-loop system where runners and scrap are immediately re-melted. This not only reduces our carbon footprint but also allows us to pass material cost savings directly to our clients in the automotive, medical device, and electronics sectors.

Steps in the Sustainable Zinc Cycle

- Low-Energy Melting: Zinc's low melting point saves up to 40% more energy than aluminum.

- Hot-Chamber Efficiency: Faster cycles mean less machine uptime per part.

- Total Recyclability: 100% of zinc waste is reintroduced into the manufacturing stream.

Frequently Asked Questions

Which zinc alloy is best for automotive structural parts?

Zamak 3 is the most widely used alloy for automotive parts due to its excellent balance of physical and mechanical properties. However, for applications requiring higher strength or creep resistance, ZA-8 or ZA-12 alloys are often recommended.

How does SunOn ensure the quality of automotive zinc parts?

We maintain IATF 16949 and ISO 9001 certifications. Our quality assurance process includes CMM inspection, mold flow analysis, material composition testing, and dynamic balance testing to ensure every component meets Tier-1 and Tier-2 supplier requirements.

Can zinc die casting replace plastic injection molding in cars?

Yes, zinc is frequently used to replace plastic when a part requires higher strength, superior EMI shielding, or a premium "metallic" feel. Because zinc can be cast with very thin walls, it can often match the weight of reinforced plastic components while offering better durability.

What surface finishes are available for zinc automotive parts?

Zinc is highly receptive to various finishes. At SunOn, we offer electroplating (chrome/nickel), powder coating, E-coating for corrosion resistance, and bead blasting for a matte, professional aesthetic suitable for interior trims.