How to Choose Between Zinc and Aluminum Die Casting

Choosing between zinc and aluminum die casting depends primarily on your part’s weight requirements, structural strength, and total production volume. While aluminum excels in lightweight, high-temperature applications, zinc is the superior choice for high-precision components requiring thin walls and maximum tooling longevity.

In this guide, you will learn to:

- Evaluate mechanical property trade-offs (strength vs. weight).

- Calculate Total Cost of Ownership (TCO) based on tooling life.

- Compare design limits for wall thickness and tolerances.

- Identify the ideal casting process (Hot vs. Cold Chamber) for your application.

Fundamental Material Properties: Zinc vs. Aluminum

The decision-making process begins with the physical characteristics of the alloys. Aluminum is renowned for its low density (approximately 2.7 g/cm³), making it the standard for the automotive and aerospace industries where every gram saved translates to fuel efficiency. Conversely, zinc is significantly denser (approximately 6.6 g/cm³), providing a "premium" feel and higher impact strength.

Zinc alloys, particularly Zamak 3 and Zamak 5, have lower melting points than aluminum. This allows for a hot-chamber casting process that is less corrosive to the machinery and significantly more energy-efficient. Aluminum alloys like A380 require higher temperatures, necessitating cold-chamber machines to prevent the molten metal from attacking the plunger system.

Common Mistakes to Avoid:

- Assuming zinc is always more expensive: While the raw material price per kg is often higher for zinc, the faster cycle times and lower energy consumption can reduce the price per part.

- Overlooking thermal conductivity: Aluminum is a superior heat sink material; using zinc for high-heat dissipation components can lead to thermal failure.

Process Differences: Hot Chamber vs. Cold Chamber

The casting method is a direct result of the material's melting point. Zinc utilizes the Hot Chamber process, where the injection mechanism is submerged in the molten metal. This allows for rapid-fire "gooseneck" injection, resulting in cycle times that can be up to twice as fast as aluminum.

Aluminum requires the Cold Chamber process. In this method, molten metal is ladled into the cold chamber for each shot. While this prevents the aluminum from melting the injection equipment, it increases cycle times and labor costs. If your project requires millions of small parts, the speed of zinc’s hot chamber process often offsets its higher material cost.

Design Constraints: Wall Thickness and Tolerances

Precision is where zinc truly shines. Because zinc is highly fluid at lower temperatures, it can flow into incredibly tight spaces that aluminum cannot reach without premature solidification.

Thin Wall Capabilities

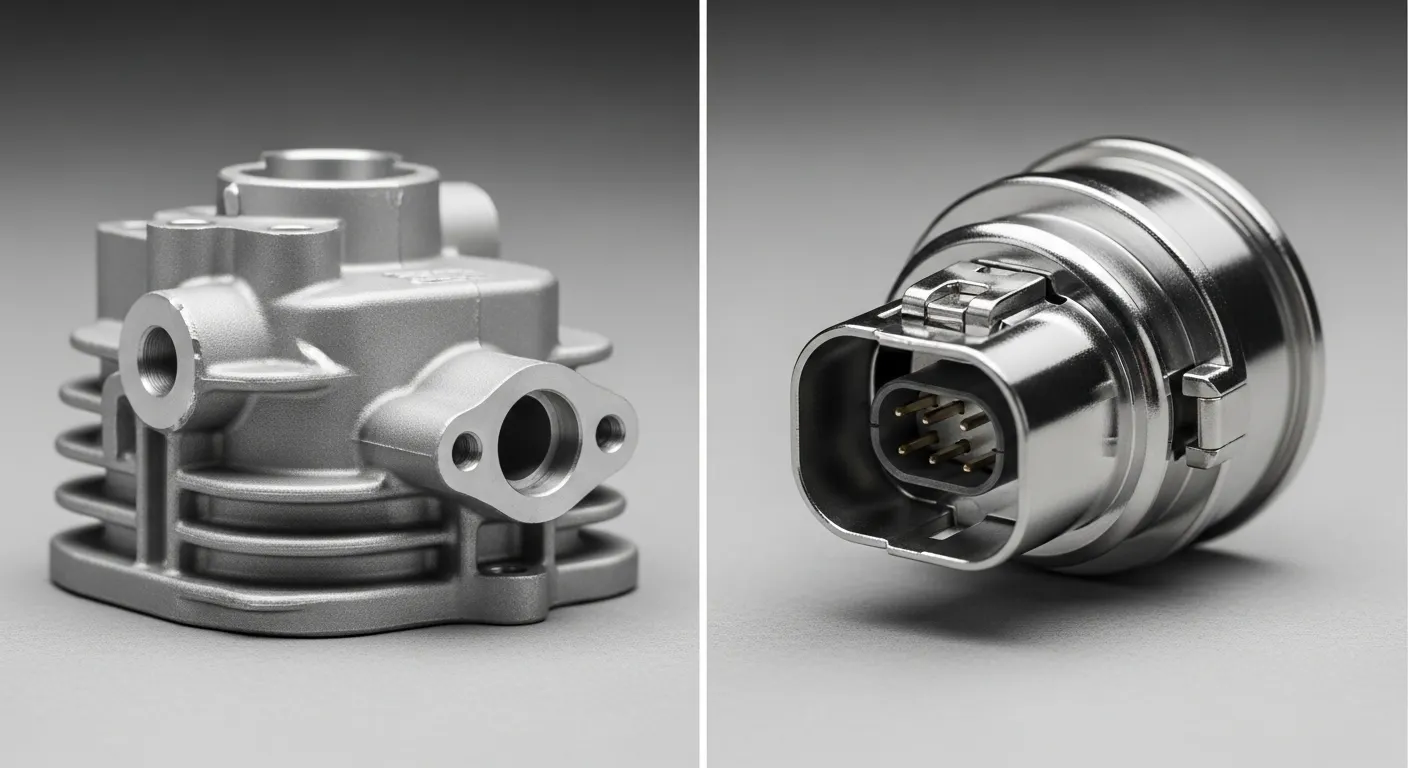

Zinc can achieve wall thicknesses as low as 0.5mm, whereas aluminum generally requires a minimum of 1.0mm to 1.5mm to ensure structural integrity. This makes electronics precision zinc alloy parts for connectors the industry standard, as they allow for miniaturization without sacrificing strength.

Precision & Secondary Machining

Zinc castings often achieve "net shape," meaning they are ready for use right out of the mold. Aluminum typically requires more secondary machining to meet tight tolerances. Zinc can often meet IT9 precision grades, while aluminum usually falls within IT11 or IT12. This precision is critical for medical device zinc die casting high precision components, where sub-millimeter accuracy is non-negotiable.

Total Cost of Ownership (TCO) Analysis

When calculating ROI, looking at the price of the metal alone is a trap. You must consider Tooling ROI.

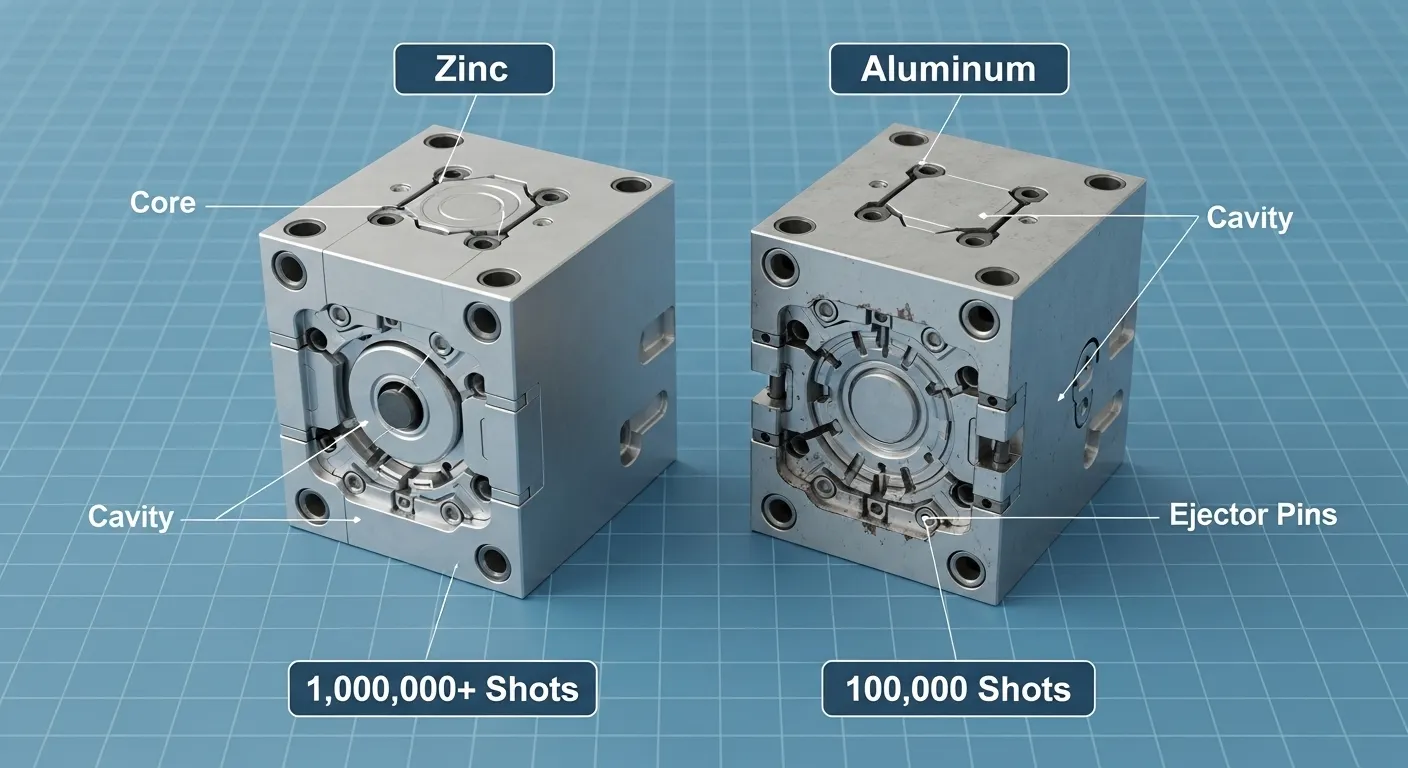

- Tooling Life: Zinc is non-abrasive and has a low melting point. A high-quality H13 steel tool for zinc can last for over 1,000,000 shots (needs verification).

- Aluminum Limitations: Aluminum is more abrasive and operates at higher temperatures. An aluminum die-casting tool typically requires refurbishment or replacement after 100,000 to 150,000 shots (needs verification).

If your production run is 500,000 units, you would need one zinc tool but potentially four or five aluminum tools. The savings in tooling often make zinc the more economical choice for high-volume, long-term production.

Application-Specific Showdown

Automotive & Aerospace

Aluminum is the undisputed king of structural automotive parts where weight reduction is the priority. However, for internal mechanisms, zinc is preferred for its wear resistance and ability to be plated. There are many advantages of zinc die casting for automotive parts, especially regarding durability and complex geometries in lock housings and fuel systems.

Electronics & Connectors

For EMI/RFI shielding, zinc provides excellent performance. Its ability to be cast into extremely thin, complex shapes makes it the go-to for automotive zinc die casting parts for vehicle components that involve delicate sensors or electrical housings.

Sustainability and Recyclability in 2026

Both materials are highly sustainable. Aluminum and zinc are 100% recyclable without losing their physical properties. In 2026, manufacturing standards place a high premium on energy consumption. Because zinc melts at a lower temperature, the "carbon footprint per part" is often lower than aluminum when considering the energy required for the casting cycle.

Frequently Asked Questions (FAQ)

Zinc alloys are generally stronger and tougher than aluminum alloys at room temperature. Zinc has higher ductility and impact strength, making it better for parts that must withstand stress without fracturing.

Zinc is superior for thin-wall applications. It can be cast as thin as 0.5mm, whereas aluminum typically requires walls of at least 1.0mm to ensure the metal fills the mold completely.

Zinc provides a much smoother "as-cast" surface finish. This makes it easier and cheaper to plate, paint, or powder coat compared to aluminum, which often requires more intensive surface preparation.

Zinc tools can last up to 10 times longer than aluminum tools. A zinc die can often produce over 1 million parts, while an aluminum die usually needs replacement after 100,000 to 150,000 cycles.

Aluminum has better natural corrosion resistance due to the formation of a protective oxide layer. Zinc usually requires a secondary coating, such as plating or chromating, to match aluminum's environmental durability.

No, zinc loses its strength significantly as temperatures rise above 100°C. For applications involving high heat, such as engine components or heat sinks, aluminum is the better choice.

Final Selection Checklist

To make your final decision, ask these four questions:

- Is weight the primary constraint? If yes, choose Aluminum.

- Does the part require sub-millimeter precision or ultra-thin walls? If yes, choose Zinc.

- Is the production volume over 200,000 units? If yes, Zinc usually offers better tooling ROI.

- Will the part be exposed to high heat (above 120°C)? If yes, choose Aluminum.

Ready to start your next project? Contact Sunon-mould today for a technical consultation and a detailed quote on your precision die casting needs.